Safe and Effective Thermal Remediation of Your Site Requires the Very Best Technologies and Engineering.

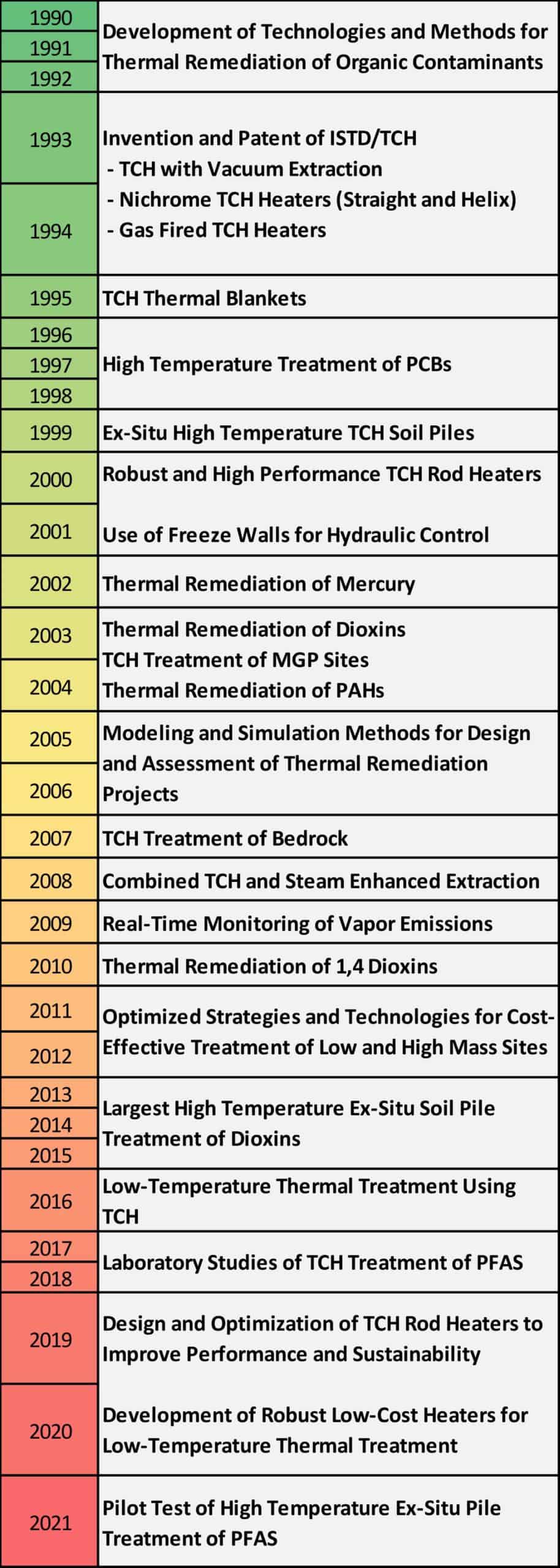

TerraTherm has over 30 years of R&D experience in developing and applying innovative technologies for the thermal remediation of contaminated soil. This work helped propel thermal remediation from an interesting idea to a safe, practical, and cost-effective remedial option for your site.

Our team of experts continues to innovate, develop new technologies, and improve existing ones to help solve your challenges and address emerging contaminants. Some of the things we are working on include:

- Developing new technologies to address emerging problems like PFAS;

- Improving the performance and reducing the cost of our technologies; and

- Enhancing the sustainability of thermal remediation.

You can’t turn off innovation or excellence!

PFAS

The need for effective and complete remediation of poly- and perfluoroalkyl substances (PFAS) at competitive pricing is growing substantially because of increased regulatory attention to this class of emerging contaminants. PFAS are known as forever chemicals because they are persistent in the environment and difficult to remove. Stockpiles of PFAS contaminated soils are growing and a permanent solution to remediate and clean these piles (and other source zones not yet addressed) is needed.

TerraTherm’s patented TCH technology effectively treats PFAS. TerraTherm has been evaluating the use of our patented TCH technology to tackle these contaminants since 2017. In fact, TerraTherm is the only thermal vendor to have successfully completed 19 high-temperature thermal remediation projects for contaminants similar to PFAS:

- Treatment temperatures between 250 and 350C

- In situ and ex situ soil pile applications.

- Optimization of in situ or in pile destruction to minimize treatment requirements.

- Advanced vapor and liquid treatment systems to meet stringent standards (e.g., >99.999999% DRE).

- Achieve extremely low soil cleanup standards:

- PCBs <25 µg/kg

- Dioxins <0.0035 µg/kg TEQ

- PAHs <60 µg/kg B(a)P Equivalent

Recent laboratory studies conducted by our partner Krüger have shown better than 99.99% removal of PFAS contaminants from soil using our TCH technology. Although PFAS were designed to resist heat, we know that at high enough temperatures, temperatures readily achievable with our TCH technology, they can be removed from the soil through both complete mineralization and volatilization and extraction. Contact our PFAS-Lead Steffen Griepke today if you would like to discuss how thermal can treat your site.

Sustainably enhance natural biological and abiotic reactions with TerraTherm’s low-temperature thermal to achieve cleanup at your site!

Robust small diameter heaters can be safely and easily installed for low cost to remediate your site!

Low-Temperature Thermal Treatment

TerraTherm is at the forefront of developing new innovative technologies for the sustainable treatment of our client’s sites. For some sites, where the COCs and remedial timeframes are suitable, gently heating to 30 to 90˚C may be a highly cost-effective approach to achieve your remedial goals. Importantly, if temperatures are kept below the boiling point of water, then expensive extraction and treatment systems are not required.

Raising subsurface temperature to 30 to 40˚C can result in increasing biodegradation rates by a factor of 3 to 4.

Increasing temperatures from ambient to ~90˚C (less than the boiling point of water) can increase the hydrolysis reaction rates of some CVOCs by >5 orders of magnitude!

These sustainably enhanced natural degradation rates can effectively remediate low to moderate mass source zones or dissolved plumes with contaminant storage zones (i.e., low permeability zones with little or no groundwater flow interbedded with higher permeability zones), in 1-3 years.

We have recently completed the development and testing of low-cost, robust heater designs that use small diameter, optimized-power output to gently heat soil to the required temperature. These heaters can be quickly and inexpensively installed in most geologies using direct push technologies.

Contact our low-temperature thermal treatment lead John LaChance to learn more about how this technology could be applied to your site.

Our optimized heater design can save costs and improve both performance and sustainability at your site!

Optimized TCH Heaters

Our optimized heater design can save costs and improve both performance and sustainability at your site! We are currently working on the re-design of our proven and reliable TCH heaters to enhance power delivery and sustainability. The aim of this work is to retain the impressive proven reliability of our heaters while at the same time, improving their performance by better focusing power delivery to specific treatment zones and increasing the power output rate. This will allow an increase in the spacing between heaters and reduce the number of heaters required to treat a site, the amount and duration of drilling, and the amount of electricity used. These changes will not affect the reliability of the heaters, but will improve sustainability, by reducing the quantity of materials consumed and the CO2 footprint.

John LaChance

John LaChance is the Vice President of Development at TerraTherm. In his 30+ year career in the remediation industry, he has worked on a range of project sites, including chemical manufacturing plants, gas stations, oil refineries, railroads, former MGP sites,...

Steffen Griepke

Steffen Griepke is the Vice President of Technology at TerraTherm. In this role, he helps clients determine if a thermal remedy would work on their project site and, if so, which thermal technology or combination of technologies would be the most cost-effectiv...

Get in Touch with TerraTherm

Have questions or need more information? Fill out the form below, and our team will get back to you as soon as possible.