TerraTherm

Your Trusted Partner in Thermal Remediation

TerraTherm partners with leading engineering firms, government agencies, corporations, and property owners in flexible, cooperative relationships to achieve cleanup goals.

Our experienced project teams and patented technologies are based on over 20 years of successful experience and R&D in the thermal remediation of soil, rock, and groundwater.

Think Thermal

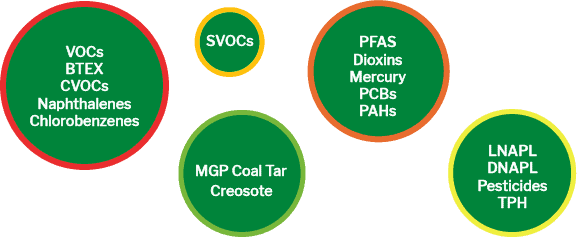

TerraTherm Treats a Wide Range of Organic Chemicals and Some Metals

Recent News from TerraTherm

Two Major Challenges with Fractured Rock Sites

Fractured rock sites are challenging to remediate because it is often difficult to determine how deep non-aqueous phase liquid (NAPL) has gone, and to define what we refer to as the “source area.” Som...

5 Things You Need to Consider When NAPL Governs the Mass Present at Your Thermal Site

Thermal remediation technologies have been used for more than two decades to address highly contaminated source zones. In the beginning, thermal was typically utilized to address volatile organic comp...

Frequently Asked Questions About High Temperature Thermal Conductive Heating for PFAS

Treating soil impacted with Per- and Polyfluorinated Substances (PFAS) is difficult to do using traditional remediation methods due to their recalcitrant nature. Because of their chemi...

A Global Leader in Thermal Remediation

Webinars & Events

TerraTherm provides the expert resources, advice, and designs you need to answer your questions and make the right decisions. We help you to determine which technology options are best for your site, design the optimal project to meet your goals, and find the most cost-effective solution. To sign up for one of our webinars to learn more about us, view our calendar of upcoming webinars and in-person events.

Get in Touch with TerraTherm

Have questions or need more information? Fill out the form below, and our team will get back to you as soon as possible.