Thermal Conduction Heating

Why Use TerraTherm's Thermal Conduction Heating Technology?

- Electrically powered and custom-fit heaters provide the most efficient and effective heating of each site. Our heating technology has been thoroughly tested, perfected, and proven.

- Predictable and reliable performance without unexpected delays or costs. Our heaters have been patented and in use since 2002. TerraTherm is the first and only thermal remediation company to gain certification of its electrical TCH heating system and heating components. This certification demonstrates the high standard of care for electrical safety we apply to every project.

- Reduce risk and liability. Our heaters are the benchmark by which all other TCH heaters are compared. Our experienced team has successfully treated 80 sites using TCH and manufactured, installed, and operated over 10,000 heaters consisting of over 500,000 ft of heater elements.

- No excessive drying of site soils. At typical sites, <1% of the soil is dried out or heated to temperatures >100°C.

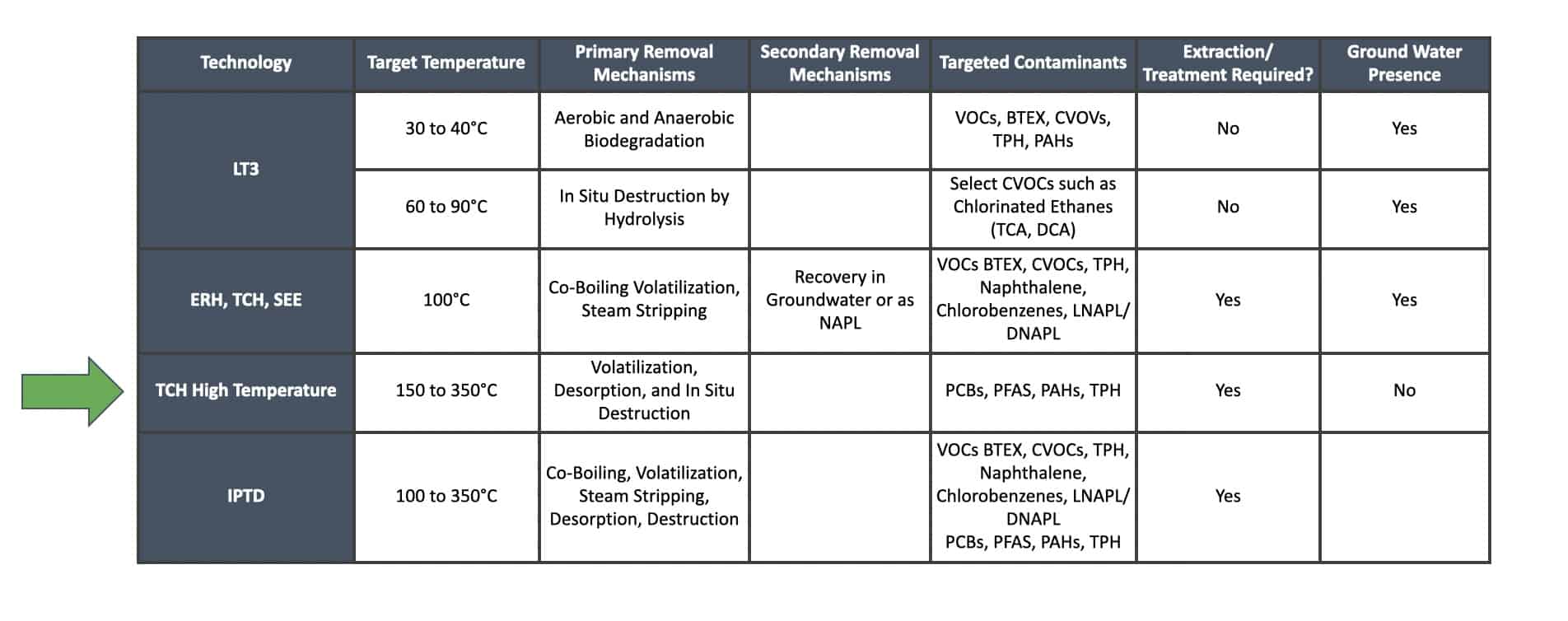

- Flexible heater designs mean you don’t have to compromise. Our heaters are able to gently heat sites to 30-90°C, 100°C, or to temperatures between 250°C and 350°C, depending on the COCs, remedial mechanisms targeted, remedial goals, and schedule.

- You can target the entire range of contaminants with our heaters: VOCs, BTEX, SVOCs, SVOCs, PAHs, PCBs, PFAS, coal tars, creosote, TPH, and more.

- Typical heating and operating durations range from 6 to 8 months, providing clients with safe, quick, and predictable restoration of their properties.

How it Works

- Heat efficiently and uniformly moves out radially around the heaters by thermal conduction (i.e., transfer of energy from the heater directly to the soil).

- At sites where the target temperature is 100°C (e.g., CVOCs), the spacing between the heaters ranges from 15 to 18 ft. This results in an operation period of 6 to 8 months.

- Steam, contaminant vapors, and air are removed from the treatment zone during heating using vapor extraction wells. At some sites, groundwater extraction is also performed to ensure hydraulic control.

- TCH can also be used at certain sites where groundwater influx is not an issue or can be controlled, to heat the soil to much higher temperatures (150 to 350°C), thereby addressing contaminants with high boiling points like PCBs, PFAS, PAHs, and dioxins.

- For high-temperature sites, the spacing between the heaters ranges between 10 and 12 ft.

- Importantly, for sites where the target temperature is 100 °C:

- Only soil within 6” of the heater dries out and is superheated (>100 °C)

- >99% of the site remains wet with temperatures between 10 and 100 °C.

Thermal Conduction Heating Applicability