Steam Enhanced Extraction

Why Use TerraTherm's SEE Technology?

- There is no room to learn on-the-job at a complex steam site. Our clients benefit from more than 20 years of experience in the design and implementation of Steam Enhanced Extraction (SEE), to deliver results safely, efficiently, and consistently.

- Your site’s hydrogeologic conditions are properly assessed by trained hydrogeologists and engineers with advanced numerical models and design tools. This ensures effective interface and coordination with the project team and importantly, utilization of all available site data to develop the most efficient and effective designs and accurate predictions of durations and utility/energy usage.

- You partner with a deep bench of thermal specialists for every aspect of a project- from design through implementation. TerraTherm has been designing and implementing SEE projects since 2007 and has treated 12 sites using SEE and is the only thermal remediation vendor with an extensive team of experienced steam practitioners including Technical Directors, Engineers, Project Managers, Data Managers, Construction Supervisors, and Lead Equipment Operators. We are more than just 1 or 2 people who have designed projects.

- Use SEE to remediate your site quickly and efficiently for lower costs. We have the largest fleet of proven and reliable SEE equipment on hand including wellheads, steam regulating manifolds, steam fittings and valves, and delivery manifold piping. In-house mechanics and engineers perform preventative maintenance and repairs to ensure your project stays on track.

- Remediation times for SEE projects range from 6 to 8 months, delivering reliable remediation for predictable site closure and/or property transfer.

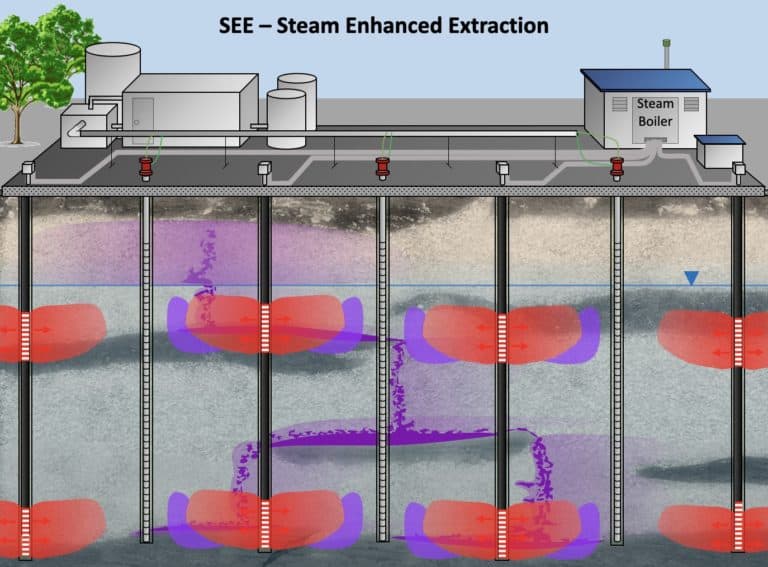

How it Works

- Steam is delivered to the subsurface through small diameter, easy to install, short screen intervals (1 to 3 ft) to allow maximum horizontal spreading of the steam and thorough heating of the targeted intervals.

- Spacing between the steam injection wells ranges between 20 and 40 feet, depending on the depth and hydraulic properties of the targeted treatment zone(s).

- During early stages of steam injection, a steam front moves out radially around the well and a condensate front consisting of condensed steam and contaminant vapors is formed.

- To ensure safe and effective pneumatic and hydraulic capture, a network of multi-phase extraction (MPE) wells is installed and operated.

- The condensate front is safely captured and removed by the MPE wells, and eventually steam breakthrough occurs.

Following steam breakthrough, a series of pressure-cycles are performed to ensure contaminant removal from low permeability zones. - Steam, contaminant vapors, and air are removed from the treatment zone using vapor extraction wells.

- All vapors and liquids are treated to appropriate discharge standards on site.

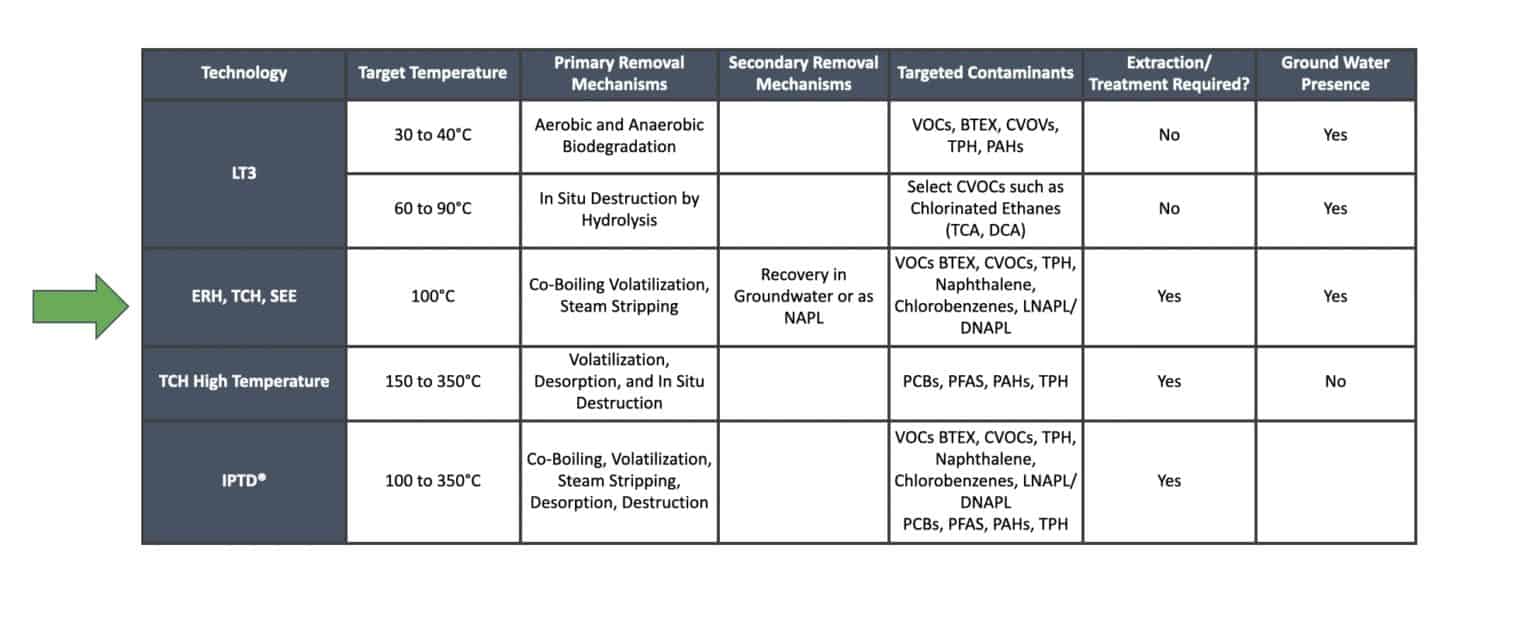

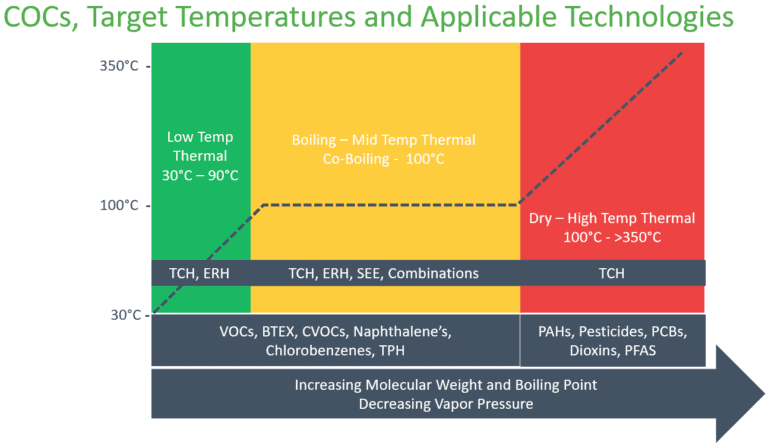

Steam Enhanced Extraction Applicability