Low Temperature

Why Use TerraTherm's Low Temperature Technology?

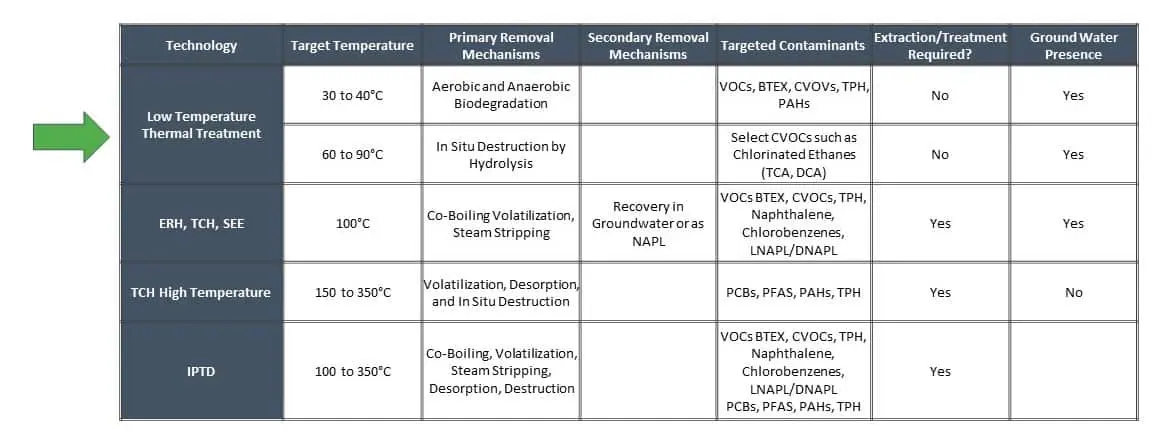

- TerraTherm’s low temperature thermal treatment technology gives you a sustainable and less costly alternative to full thermal treatment. Low temperature thermal treatment gently heats the treatment volume to temperatures between 30 and 90°C to enhance biological and abiotic contaminant degradation mechanisms without the need for expensive extraction and treatment systems.

- Lend nature a helping hand. Chemical reactions are temperature dependent, the higher the temperature the faster the reaction rate.

- For biological reactions of interest, heating to 30 to 40°C can result in a 3-4 times increase in the reaction rates, which can reduce biologically mediated cleanup times by similar factors.

- The rate of abiotic reactions such as hydrolysis can also be substantially increased by increasing the temperature. For example, the hydrolysis half-life of carbon tetrachloride (the amount of time for half of the mass to be degraded by hydrolysis) at 15°C is ~20,000 years, whereas at 90°C it is reduced to ~100 days.

- ISCO and ISCR effectiveness can be optimized and reduce your project’s cost. When combined with TerraTherm’s low temperature thermal treatment technology, the reaction rates of injectants can also be increased with increased temperature, which results in improved efficiency and reduced cleanup times. Low temperature thermal treatment combined with certain injection technologies also reduces the number of injections required and the costs of cleanups.

- Installation can be performed using flexible and inexpensive direct-push technology to best fit your site conditions and lower your project costs. TerraTherm’s low temperature thermal treatment heaters are small diameter (e.g., 2-inch) and use low-cost but robust electric powered heaters and well materials to make installation cheap, easy, fast, and sustainable.

- More uniform and predictable heat-up for your site. Our low-cost electric low temperature thermal treatment heaters provide constant and adjustable power input and heating 24/7, resulting in faster more uniform heating, which can reduce the cost of your project and increase its effectiveness.

- Low temperature thermal treatment gives you a more robust and lower cost O&M than other technologies. Unlike other low-temperature technologies that rely on circulating fluids through piping and the subsurface, our low temperature thermal treatment technology does not require freeze protection and there are no concerns or long-term O&M costs associated with leaks, replacement of pumps/valves, and fouling.

- Use low temperature thermal treatment to green-up and make your remediation project more sustainable! Renewable sources of electricity can be used for heating and our heaters and electrical cables and equipment are fully reusable, which makes the carbon footprint of our low temperature thermal treatment technology very low as compared with full thermal remediation technologies (e.g., 100°C) or other aggressive technologies, especially if it is used to enhance naturally occurring biological and abiotic degradation.

- Low temperature thermal treatment can be used to address sites with low mass or concentrations of select VOCs and SVOCs, BTEX, CVOCs, and LNAPL/TPH, and where remedial timeframes are longer (e.g., 2-3 years).

How it Works

- Small diameter heaters are installed using direct push methods on a regular pattern throughout and around the targeted treatment zone.

- The spacing between the low temperature thermal treatment heaters depends on the target temperature, depth and interval of treatment, rate of groundwater flux (if below the water table), and project schedule. Heater spacings of 12 to 18 feet are typical.

- Heat efficiently and uniformly moves out radially around the heaters by thermal conduction (i.e., transfer of energy from the heater directly to the soil).

- As targeted subsurface temperatures are well below 100°C, separate extraction wells and extraction and treatment of steam, contaminant vapors, air, and groundwater are not required.

Low Temperature Applicability