In-Pile Thermal Desorption®

Why Use TerraTherm's In Pile Thermal Desorption or IPTD® Technology?

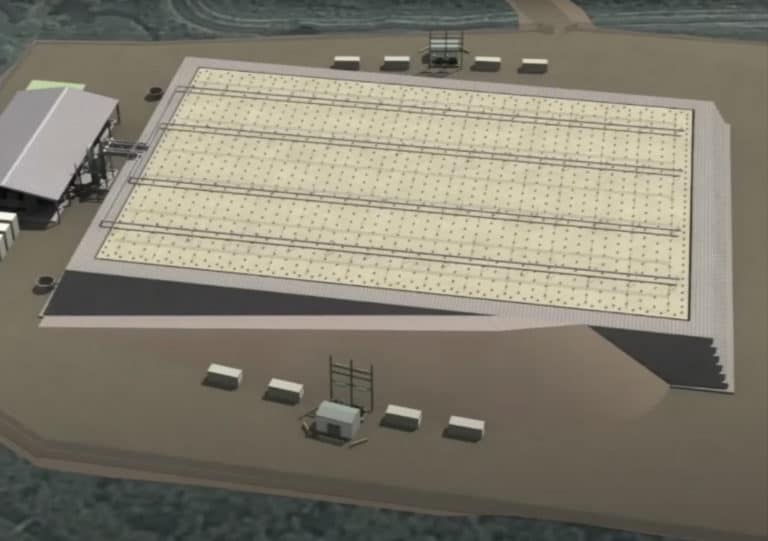

- Reduce your risk and liability by choosing our proven IPTD technologies and designs. TerraTherm has successfully treated over 135,000 cy of soil and sediment using IPTD and its patented TCH technology for difficult to remediate contaminants similar to PFAS such as PCBs, dioxins, and PAHs. Piles have been designed to treat as little as 50 cy up to 60,000 cy in one batch.

- Our IPTD technology treats soil fast and effectively. Heating and treatment can be completed in as little as several weeks depending on designs, contaminants, and remedial goals. Stringent soil standards can be achieved even for recalcitrant contaminants like PFAS such as PCBs, dioxins, and PAHs.

- IPTD is a cost-effective alternative if off-site disposal is not an option. On-site IPTD may be a cost-effective option for shallow sites where in situ treatment is not practical and for contaminants like PFAS, PCBs, dioxins, and PAHs where off-site disposal is costly or outright prohibited.

- When safety matters for you. The largest IPTD project in the world (92,000 cy), which involved the remediation of soil and sediments contaminated with dioxins, was completed successfully and safely in the city of Da Nang, Vietnam. Extracted vapors and liquids were successfully treated and all human health and environmental discharge, worker, and resident standards were met. TerraTherm applies the most rigorous and effective standards to the design, construction, and operation of its remedial systems, including IPTD.

How it Works

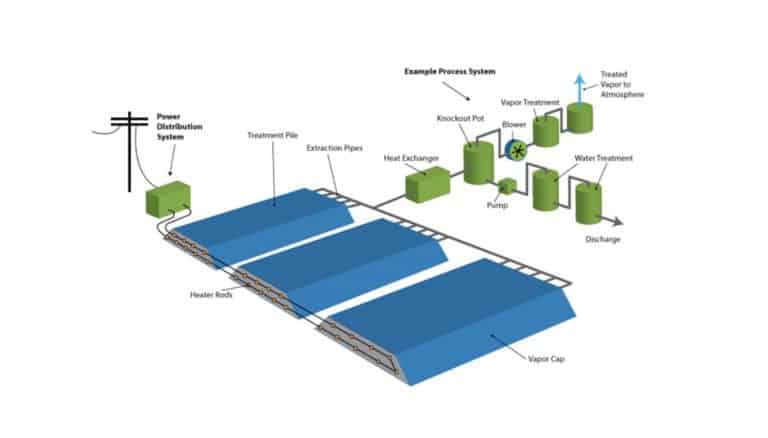

- Our IPTD approach involves placing contaminated soil and/or sediment within an engineered above-ground, fully covered, and insulated treatment pile structure, and then heating the soil to the required temperature to destroy and/or remove the contaminants over periods of several weeks to several months.

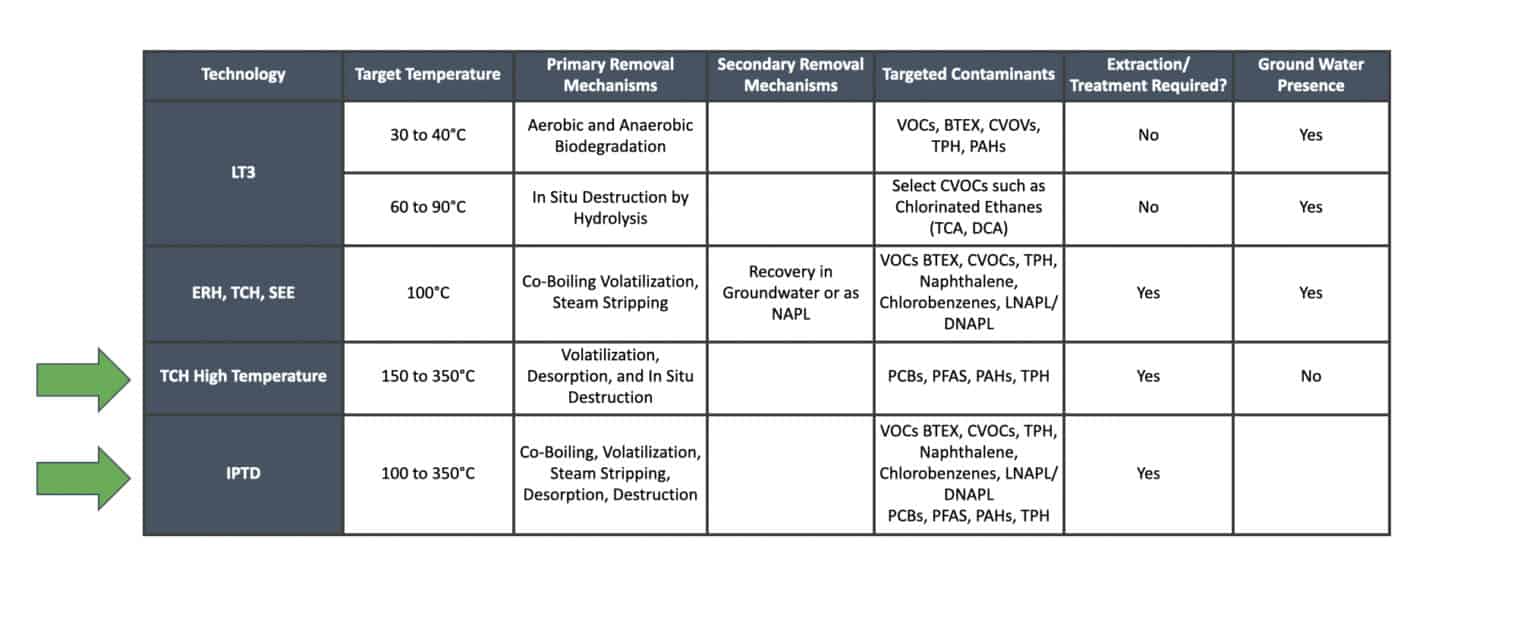

- The design temperature and treatment period is dependent on the contaminants, remedial goals, and design of the pile. For example, several weeks at 100°C would effectively treat soil contaminated with CVOCs, while soil contaminated with SVOCs such as PCBs or PFAS might require 250°C to 350°C for several months.

- Pile volumes as little as 50 cy and up to 70,000 cy have been implemented. The size of the pile depends on the volume of material to be treated, space available, electrical power available, and desired schedule.

- Sometimes the best option is to construct several small to moderate size piles (e.g., 3 to 4 piles each 500 to 5,000 cy) and treat the total volume in a series of batches. In this way, several piles can be heating while others are being unloaded and then reloaded for subsequent treatment. This reduces equipment size and power requirements, while at the same time, efficiently treating a large volume.

- Heat and vacuum are applied simultaneously to the soil with an array of horizontal or vertical TCH wells and horizontal vapor collectors, all within an insulated, covered treatment pile.

- The heater wells typically operate at temperatures of 400 to 800°C.

- Just as with in situ TCH, when the soil is heated during IPTD, organic contaminants are vaporized and/or destroyed by several mechanisms including:

- Evaporation;

- Boiling of water and attendant steam distillation;

- Volatilization of the contaminants;

- Oxidation; and

- Pyrolysis (chemical decomposition in the absence of oxygen).

- The vaporized water and contaminants are drawn into the vapor extraction wells. Contaminant vapors are then removed from the produced vapor stream at the surface with an air quality control (AQC) system and any liquids produced are treated using a liquid treatment system.

- Only after all the water has been boiled off is the soil temperature able to rise above the boiling point of water (100°C). Therefore, a high temperature IPTD (250°C to 350°C) for the treatment of PFAS, PCBs, etc. requires a longer heating duration than heating to 100°C for treatment of VOCs and CVOCs.

In-Pile Thermal Desorption® Applicability