Electrical Resistance Heating

Why Use TerraTherm's ERH Technology?

- Safe, reliable, and effective technology to treat your site. TerraTherm’s Electrical Resistance Heating (ERH) systems are specially engineered and designed to safely address a wide range of conditions that may be present at your site, including working in, around, and beneath buildings and infrastructure.

- Discrete length electrodes and power control strategies customized to your site’s geology. Each ERH system is custom designed to match your site’s specific conditions and configuration ensuring uniform and effective heating. This includes using multi-stacked, discrete-length electrodes and individual electrode power control. A one-size approach to ERH does not fit all sites, and long continuous electrodes are a cheap compromise that can severely impact performance.

- Advanced grounding and bonding designs leave no electron behind or unaccounted for. Our wellfields are designed to be safe to work in and around during ERH operation. Extensive testing is performed during start-up and operation, and a comprehensive grounding and bonding system is installed at each site to ensure control and accountability for all voltage potentials and currents. Our ERH systems minimize and eliminate, to the maximum extent possible, safety and performance issues associated with stray currents.

- Your project is supported by an experienced team grounded in the principles and physics of electrical engineering. TerraTherm has successfully treated 55 sites around the world using ERH. Our team of experienced electrical engineers and ERH practitioners is ready to meet the challenges of your site. We don’t just install electrodes in the ground and hope for the best, our team brings a fundamental understanding of the electrodynamics of efficient and safe application of three-phase ERH to heat the subsurface, to every aspect of the design, construction, and operation of your project.

- We have received multiple EBJ Project Merit Awards for project performance including one for a complex ERH project in the Midwest. At the site, we removed over 200,000 lbs of CVOCs under difficult conditions, which included routine flooding, low electrical resistivity, high groundwater flux, and 4 times the estimated starting mass of CVOCs. TerraTherm’s team of ERH engineers and practitioners were able to modify our design and operational strategies on the fly to ensure this project was completed safely and met all performance goals with minimal disruptions to schedule and budget.

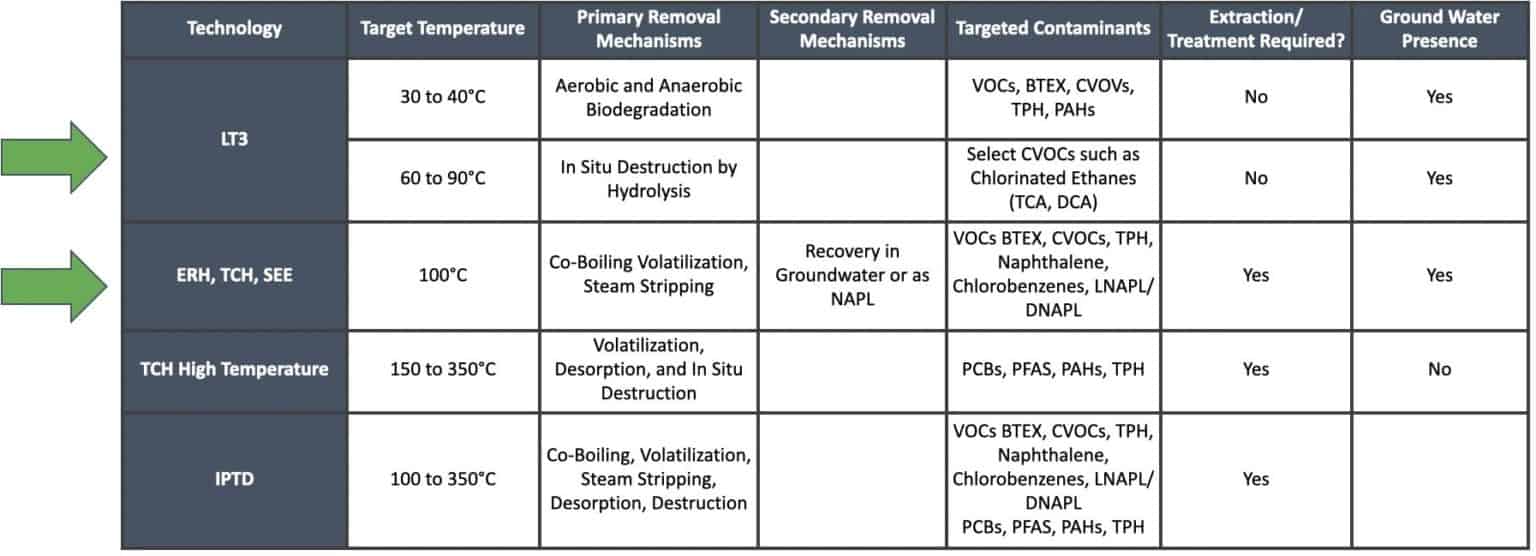

- TerraTherm brings an unbiased approach to determining the best technology or combinations of technologies to effectively treat your site. We offer all the major thermal remediation technologies: ERH, TCH, and SEE and do not attempt to sell a preferred technology for every site. If ERH is the best and most cost-effective solution for your site, that is what we will recommend.

- ERH can efficiently and effectively treat a wide range of contaminants at your site. Whether your site has VOCs, BTEX, CVOCs, Naphthalene’s, Chlorobenzenes, TPH/LNAPL, or combinations thereof, ERH can meet your remedial goals. Again, we offer all thermal remediation technologies, and if ERH is the most cost-effective at meeting your remedial goals, it is what we will recommend.

- If your project needs to be remediated in a short timeframe. ERH projects can be completed in less than a year – from the start of design, through implementation, and finishing with demobilization. Typical heating and operating durations range from 6 to 8 months. Yes! DNAPL source zones can be cleaned up and site closure achieved in less than a year using ERH!

How it Works

- Standard 3-phase AC current is applied to custom-engineered finite-length electrodes using state-of-the-art, power delivery and control systems (PDS).

- The PDS is designed to ensure safe and efficient delivery of properly phased voltages and currents to the electrodes to provide optimum heating performance.

- When energized, our ERH systems provide 3-phase alternating voltages and currents to the electrode network.

- The voltages applied to the electrodes induce current flow through the soil between the electrodes.

- The amount of current and heating is dependent on the electrical resistivity of the soil and the spacing of the electrodes.

- Our ERH systems are capable of safely delivering a full range of voltages and currents to address typical soil conditions like sand, silt, clay, till, and sedimentary rock.

- Because soil resistivity is inversely proportional to soil moisture, maximum treatment temperatures achievable with ERH ranges between 100 and 125°C (the boiling point of water) for typical hydrostatic conditions.

- Once the water is boiled off, effective heating ceases with ERH due to the very low soil moisture levels and corresponding very high electrical resistivities.

- Steam, contaminant vapors, and air are removed from the treatment zone using vapor extraction wells.

- All vapors and liquids are treated to appropriate discharge standards on site.

Electrical Resistance Heating Applicability