Project: ERH Remediation of Active Gas Station

Location

Washington

Contaminants

TPH-g and BTEX

Volume

21,800 cy

Goal

Remove LNAPL and reduce disolved phase concentrations by at least 90%

Number of Heaters

76

Mass Removed

19,000 lbs.

Technologies

Important Project Details

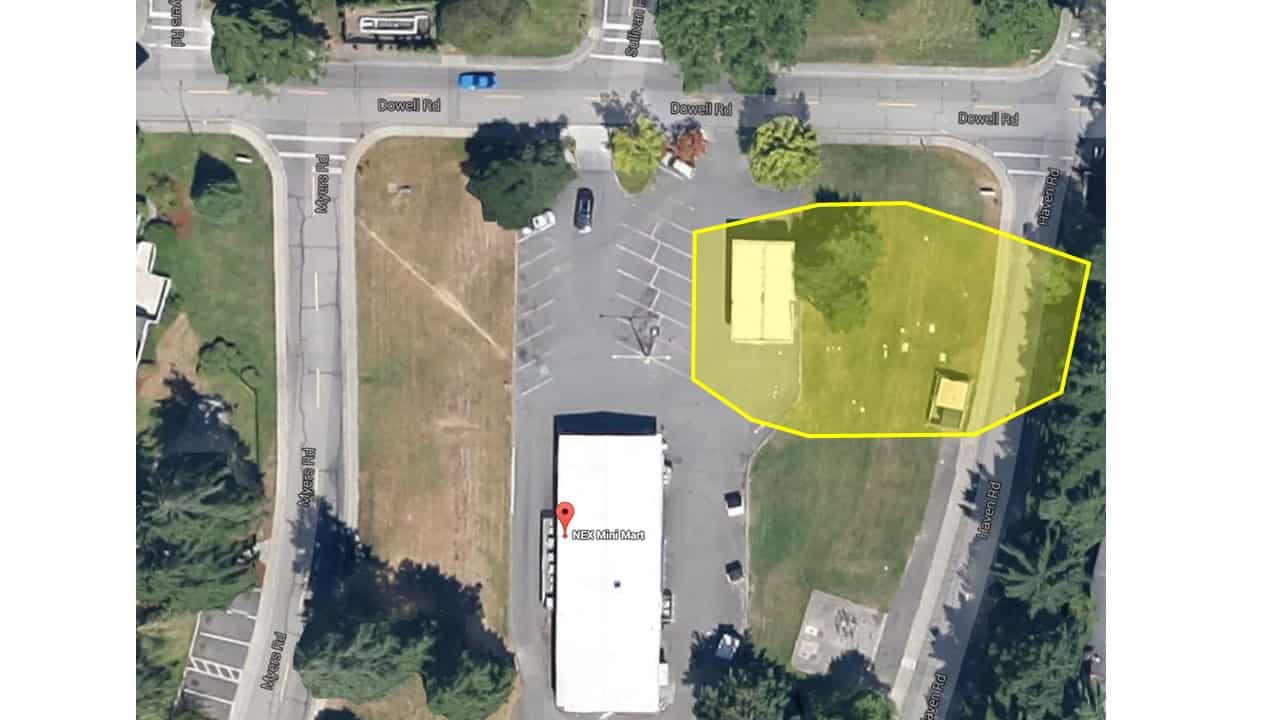

Approach: Electrodes were placed across the steeply sloping 12,800 ft2 treatment area. Heating extended to a maximum depth of 52 ft below ground surface. The electrode design included a shallow heating element in the fill/till and a deep heating element in the outwash. Each electrode also contained a co-located MPE well capable of “slurping” LNAPL from the top of the groundwater table.

Challenges: To uniformly heat the treatment volume, energy input to the fill and till layers had to be nearly identical to the level delivered to the outwash. To accomplish this, the shallow and deep electrode elements were operated at separate voltages and currents. As steam extraction during ERH lowers the groundwater table, the depths of the MPE slurping stingers had to be readjusted throughout the project.

Results: Confirmatory soil and groundwater samples showed that LNAPL had been removed and dissolved phase contaminant concentrations were reduced by an average of 99%.

What Makes this Project Unique

Electrical Resistance Heating (ERH) was selected to address both soil and groundwater impact within the source area. Underlying geologic units included sandy silt, fill, dense till, and a deep gravel outwash. Due to their varying electrical conductivities, different voltages

and currents were applied to the distinct soil layers using a system of stacked electrodes. A multi-phase extraction (MPE) system was used to remove LNAPL from the top of the groundwater table and captured steam and contaminant vapors from the vadose zone.