Fractured rock sites are challenging to remediate because it is often difficult to determine how deep non-aqueous phase liquid (NAPL) has gone, and to define what we refer to as the “source area.” Some sites have NAPL in the fractures and some have most of the mass trapped in the matrix, diffused into it over decades.

In this blog post, we discuss the two main challenges when working on fractured rock sites:

- How to decide on the thermal treatment volume without making the problem worse.

- How to design and implement an effective and safe thermal system.

More details are available in the on-demand webinar, Thermal Conductive Heating – The Remedy Option for Deep Bedrock.

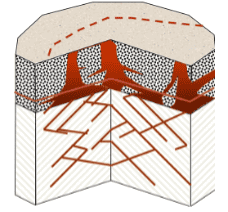

Determine Thermal Treatment Volume

For any aggressive source treatment to be cost-effective, the right volume must be treated. As illustrated below, it may be relatively easy to determine the treatment area in the overburden, but much more difficult in the deeper bedrock where the fracture pattern can be chaotic. Generally, most of the contaminant mass resides within and above the more highly weathered upper portion of the bedrock, in contrast with the deeper rock where fractures tend to be fewer and more widely spaced. The target treatment zone for thermal sometimes does not extend below the bottom of the weathered bedrock. At some sites, treatment of a small mass deeper in the fractured bedrock is desired; in those cases, the heaters are extended to heat and treat to the desired depth.

When drilling, the shaking of the ground may disturb the NAPL, and in some cases may cause the NAPL to move deeper. To minimize the risk, careful drilling, often using diamond coring, must be used. This limits the number of boreholes drilled, despite the fact that the complex geology would have otherwise demanded more drilling and sampling. As a result, the source area is often less well defined than for sites with the contaminants of concern (COCs) in overburden deposits.

Design and Implement an Effective and Safe Thermal System

Once the treatment volume has been set for a fractured rock site, the second major challenge is how to design and implement an effective and safe thermal system. Our team has gathered five key lessons from our experience at bedrock sites.

- Heating fractured rock sites with steam alone is very difficult, requiring very long heating durations and making hydraulic and pneumatic control a challenge.

- Thermal conduction heating (TCH) has proven very effective for heating of the matrix blocks by simple heat transfer from hot borings.

- Extract fluids from each heater borings to ensure that the vapors we generate have a place to go – back towards the heaters and out and up through co-located vacuum extraction wells.

- Electrical resistance heating (ERH) is applicable in some types of bedrock, typically ones with electrical resistivity values below 500 Ohm-meters. Porous and wet sandstone, for example, can be heated using either ERH or TCH. In drier rock with modest porosity (on the order of 10% or less) and deep crystalline rock, only TCH can achieve boiling temperatures and ensure proper thermal treatment because electric current flow will be limited.

- At sites with a lot of groundwater flow in some fractures, the use of steam injection to heat those fracture zones can help optimize the treatment, but the matrix must still be heated in order to remove most of the mass. The combination of TCH and steam injection is promising.

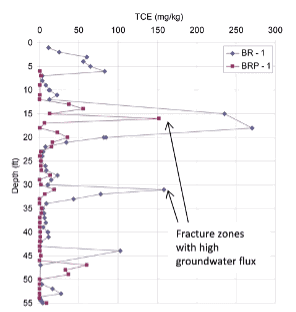

At one site, our team succeeded in heating the matrix blocks, but not the fractures where water flowed. This meant that the reduction of TCE concentrations in the rock samples was more modest near the fractures, as illustrated in the plot below.

Water flowed rapidly in fractures at depths of 17 and 31 feet. where the TCE reduction was modest. We believe that the cold groundwater flow kept the temperature low enough that the TCE could not be boiled and removed from the matrix in those locations. In contrast, TCE concentrations in the matrix blocks away from the fractures were reduced to modest levels.

At another site, we treated a 100-foot deep TCE site using TCH. The figure below shows the Tier-1 system used. Rock sampling during installation was used to optimize the treatment volume – and the shape changed a lot based on the data.

This site was successfully heated and treated without the need for steam injection to enhance treatment of the fractures. Extraction wells co-located with each heater ensured that the TCE was captured. The wells also enabled sampling of the vapor stream from all areas of the site to document that TCE levels were reduced by approximately three orders of magnitude by the treatment.

In conclusion, TCH is the most robust and predictable thermal remediation method for removing DNAPL from fractured rock.

Watch this webinar on-demand, Thermal Conductive Heating – The Remedy Option for Deep Bedrock, to learn more about vaporizing NAPL from fractured rock sites.

08.30.24