Federal guidance about per- and poly-fluoroalkyl substances (PFAS) remediation may be on the horizon, but information about treatment options and their efficacy is often still murky. Research and development often result in more questions than answers, leaving consultants feeling in limbo.

However, research is being done—including by us—and those studies show that thermal heating is a viable PFAS treatment option. In this blog post I’ll share our most recent research about how thermal technology addresses PFAS.

Existing Research About Thermal Remediation of PFAS

Over the past year we’ve expanded on the work done by our European partner, Kruger, and conducted research exploring thermal treatment of PFAS impacted soil. Previous research demonstrated that heating soil to temperatures of 350° C to 450° C effectively “removes” target list PFAS compounds.

A significant question remained: how were the PFAS removed?

Was it through complete mineralization? Transformation to a smaller molecular weight non-target PFAS compound and volatilization? Transformation to a non-target PFAS compound? Or maybe a combination of all of these? Our most recent research focused on trying to answer some of these questions while implementing a lower gas flow rate through the soil to promote PFAS mineralization, combined with exploring vapor treatment incorporating high temperature catalyst media to promote near complete destruction of target and non-target PFAS. While the study confirmed several key facts about the efficacy of thermal treatment on PFAS impacted soil, we are left with additional concepts to explore in future research.

Study Design

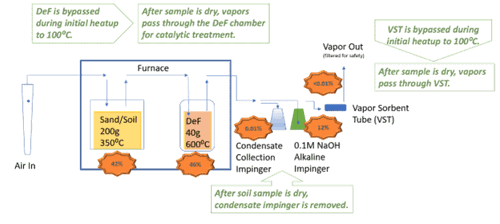

Our latest PFAS bench scale study design included a fortified clean sand and water matrix, spiked with a solution of perfluorooctanesulfonic acid (PFOS). The spiked material was then heated in a chamber at 350⁰ C for seven days. The test system was purged at a constant low flow rate such that the flow path flowed through the heated chamber and into a condensate collection flask during the boiling phase (up through 100⁰C); then during the high temperature phase (>100⁰C), the vapor flowed from the heated chamber through a high temperature vapor catalyst material (three different material types were tested) followed by an alkaline impinger, followed ultimately by a vapor sorbent tube.

Results

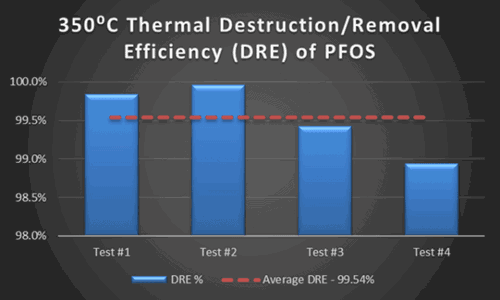

As was expected, the results of the targeted PFAS analysis confirmed over 99% removal of PFAS compounds from the soil at a treatment temperature of 350⁰ C for seven days. Even at concentrations that would be considered very high in the environment (~250 mg/kg), thermal treatment proved effective at achieving soil concentrations below the recently published US EPA Regional Screening Level (RSL) for residential soil for PFOS (0.18 mg/kg).

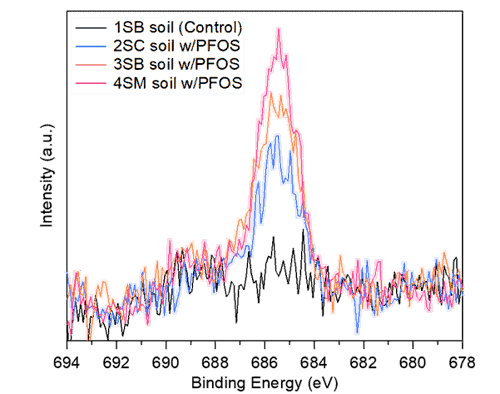

One of the most interesting things we observed was the transfer of fluorine mass from the spiked sand chamber into the catalyst chamber. This implies that there is a lot of complex chemistry going on at the higher temperature thermal treatment, and that a substantial fraction of the fluorine mass that starts in the spiked soil as PFOS transforms to a volatile form of PFAS and is present in the vapor phase leaving the heated soil (and then subsequently recaptured in the catalyst). We are in the midst of planning future research to explore what chemical species are present in the vapor and which compounds can be monitored during remediation as indicators of progress or remedy completion. Another surprising observation was detecting the presence of metal fluorides in the treated soil. X-ray photoelectron spectroscopy (XPS) surface characterization of the solid materials (treated soil and catalyst material) was performed by researchers under the direction of Lynn Katz, Ph.D. at the University of Texas at Austin. The results indicate that there is chemistry happening with PFAS species, and the breakdown products react with the surface minerals to form more stable inorganic fluoride species. Future research will try to re-visit this surface chemistry analysis in more detail.

Finally, this research demonstrated that the concept of vapor treatment involving a catalytic material, followed by an alkaline impinger, effectively treated the vapor emissions from the system to non-detect for target PFAS compounds. Furthermore, as discussed below, we were able to close the fluorine mass balance and account for all of the spiked fluorine mass within the system (soil, catalytic material, condensate, and alkaline impinger), meaning that no (or extremely small amounts of) non-target PFAS compounds would be emitted to the atmosphere if a system incorporating these components were used at full-scale to treat PFAS impacted soil.

Closing the Mass Balance

Closing the mass balance in the experimental system proved challenging at first, when we simply limited ourselves to analyze samples for the targeted PFAS compound list. Even when we analyzed the sample matrices for fully mineralized fluorine (in the form of the fluoride ion), a significant amount of mass was still missing.

After discussions with Eurofins PFAS analysis experts, our research team decided to perform additional testing using the combustion ion chromatography (CIC) technique. For this approach, we opted to combust the solid samples (treated soil and spent catalyst) in their entirety: i.e., analyzing for total fluorine (both organic and inorganic forms). Once the CIC analysis was completed, it revealed the missing mass and also illustrated where the fluorine mass resided in the treatment system. Approximately 42% of the fluorine mass remained in the treated soil in some other stable organic or inorganic form (not analyzed in the target PFAS analysis and not present as extractable fluoride), approximately 46% of the mass was captured in the vapor phase catalyst, a smaller percentage (approximately 12%) was seen in the alkaline impinger, and negligible amounts were seen in the condensate and vapor sorbent tube.

Future Work

While several useful conclusions were drawn from this work, it also highlighted how much is still unknown about this category of emerging contaminants. Future work hopes to address some of the remaining unknowns by looking at real time vapor analysis, more extensive CIC analyses, analysis for PFAS precursors, and other investigative techniques. We also hope to have an opportunity to test out ways to incorporate the catalytic material into our vapor treatment process.

Do you have a candidate PFAS site ready for pilot scale implementation of thermal? We’d love to discuss how this technology could work for your site and how we could potentially conduct a more in-depth real world study on the site soil, condensate and vapor.

11.10.22

Alyson Fortune

Alyson Fortune joined TerraTherm in 2012 as a Senior Scientist with over 15 years of experience in the environmental industry, including experience with source testing, analytical laboratory testing, and environmental consulting. Alyson is acting as the data q...