“The successful completion of this project resulted in a cost avoidance of $218M by reducing the environmental remediation timeline by 140 years.”

These words reflected on a recently completed Thermal Conductive Heating (TCH) project performed by TerraTherm under the supervision of the FAA and Amentum at a former jet fuel site. However, an oft heard refrain is that thermal remediation is an expensive, if not the most expensive source zone treatment technology. But is this true?

This blog will help environmental program managers compare in situ remediation technologies in terms of total lifecycle cost. We’ll take a closer look at the costs of using thermal remediation to cleanup difficult to treat contaminant source zones and hopefully clear up some of the misconceptions about how thermal remediation stacks up.

Why is Thermal Remediation so Expensive?

When comparing lifecycle cost of your remediation technology options, it’s important to understand all the parts of the equation. Thermal remediation, whether in the form of TCH, Electrical Resistance Heating (ERH) or Steam Enhanced Extraction (SEE) are all aggressive, highly predictable, and reliable source zone removal technologies. Significant efforts and resources are involved in the successful completion of a thermal project because the entire contaminant mass (>99%) is mobilized and removed from the subsurface in a relatively short time frame.

For example, the cost of materials is significant due to the chemical compatibility that is required to handle corrosive chemicals such as CVOCs or other compounds, as well as the cost of energy to heat the subsurface. While these costs can appear high in the short term, they are competitive with life cycle costs for other source zone treatment technologies.

Lifecycle Costs of Source Zone Cleanup is Comparable Across Remediation Technologies

While it can be challenging to find an apples to apples comparison of life cycle costs for source zone technologies outside of a formal feasibility study, this 2014 book “Chlorinated Solvent Source Zone Remediation” by Kueper et al. tackled this very question.

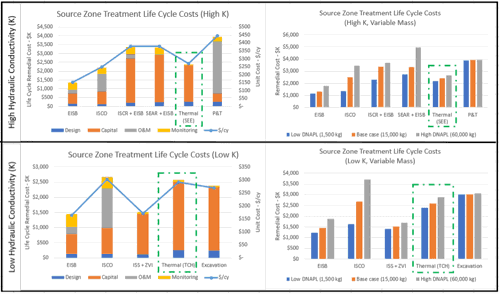

The authors estimated the life cycle costs for remediating two hypothetical source zones with the ultimate goal of reducing source mass by >90% and/or mass flux by 90-95%. One source zone assumed a high hydraulic conductivity (K) and the other a low hydraulic conductivity, but otherwise all other subsurface conditions were identical. For each source zone, they also varied the amount of mass to assess cost sensitivity to changes in mass for each technology.

Figure 1 presents the total and unit cost for each of these scenarios and compares the different technologies based on costing data assembled by Kueper et al.

There are two key takeaways from this work. The first and most important takeaway, is that the cost between the different technologies is very comparable for both Low K and High K source zones.

Thermal Remediation is More Cost Effective as Mass Increases

The second take away from Kueper et al. is that the cost of a thermal project changes very little when there is significantly more mass (e.g., 1,500 kg vs. 60,000 kg) in the same treatment zone. That’s because, the starting mass does not affect the in situ design or heating approach and only results in marginal increases in cost associate with sizing of the off-gas treatment system.

Speed and Efficacy of Thermal Technologies

The other benefit to thermal that has potential cost savings, especially when redevelopment is a driver, is the speed and efficiency of remediation. The sooner the site can be restored, the sooner the property can be redeveloped, sold, or otherwise beneficially reused.

TerraTherm’s thermal projects consistently achieve clean up goals within an average timeframe of 12-15 months for design, construction, operation and demobilization. In fact, the mass removal efficiencies that In Situ Thermal Remediation (ISTR) achieve are arguably only comparable to excavation.

Furthermore, following thermal remediation, the increased groundwater and soil temperatures enhance other degradation pathways, which lead to further mass removal and polishing in and downgradient of the treatment zone. Other source zone treatment technologies that require unknown iterations of injections or extraction require significantly more time. The average SVE system operates between 1 to 5 years, removing significantly less mass than thermal and typically failing to meet regulatory cleanup levels at DNAPL source sites according to the EPA’s A Citizen’s Guide to Soil Vapor Extraction and Air Sparging.

Match the Remediation Technology to the Problem and Project Drivers

If you need to build a bridge from point A to point B, then you need to pick the approach that has sufficient resources to complete the project. Choosing an approach that costs 50% less may leave the job unfinished and you and your client hanging.

The same applies to cleaning up contaminant source zones. Choosing a cheaper remediation technology for a challenging site may not reach the remedial goals in the desired timeframe. Conversely, some sites may not require thermal remediation, and other less aggressive and less costly approaches such as in situ chemical oxidation (ISCO) or in situ chemical reduction (ISCR) may be successful.

While thermal remediation costs significantly more than Monitored Natural Attenuation, MNA won’t achieve stringent remedial goals for DNAPL source zones in meaningful or predictable timeframes. Thermal remediation reliably and safely cleans up difficult sites with recalcitrant chemicals to stringent goals in less than a year from start to finish.

The key is to identify and match the correct technology to the problem being addressed and the project drivers.

How is Thermal Remediation Cost Competitive for Source Zone Treatment?

Thermal remediation may not be cheap, with costs ranging between $100 to $200 per cubic yard, depending on the size of the site. However, when compared to life cycle costs of other source zone treatment technologies, thermal can be very cost competitive. Additionally, many other remediation technologies require significantly more time, do not achieve the same level of treatment with a high degree of certainty and delay a site’s full return to beneficial reuse.

While thermal isn’t recommended at all sites, we will work closely with our clients to ensure selection of a cost-effective thermal solution to meet project goals. Be sure to also check out our post on performance guarantees which discusses how TerraTherm manages uncertainty in their design approach.

07.28.22

Sam Nienstedt

Sam Nienstedt is TerraTherm’s Technologist. He keeps the project management team informed of projects’ statuses by monitoring and processing real-time operational data that comes in from the field and preparing operational reports. As part of the Technolog...