If you’re new to the environmental services industry, you may know about thermal remediation but not understand the differences between the different heating technologies. Each technology has its own strengths and weaknesses, however, that are important to be aware of when selecting a remedy for your site. In this blog post, I’ll explain what thermal conduction heating (TCH) is, how it works, and the contaminants it is most suited to treat. In upcoming posts, you’ll get a similar overview from my colleagues about electrical resistance heating (ERH) and steam enhanced extraction (SEE).

Where did thermal conduction heating (TCH) come from?

During the 1970s and 1980s, there was a growing concern in the United States about contaminated sites and the health risks they posed to the communities surrounding them. The Comprehensive Environmental Response Act, the Compensation and Liability Act (CERCLA), and the Superfund Amendments and Reauthorization Act (SARA) were created to better respond to these sites and focused on developing initiatives regarding public health, permanent remedies, and innovative treatment technologies. One of the technologies that grew out of the legislation was thermal conduction heating. TCH was invented in the 1990s by Shell TerraTherm. In February 2000, TerraTherm was founded, and we have been utilizing and optimizing the technology ever since.

How does TCH work?

When utilizing thermal conduction heating, heat is applied to contaminated soil by heater wells, and vacuum is applied to the soil by screened vertical vapor extraction wells (VEWs) or by multi-phase extraction wells (MPEs).

The heat causes the contaminants in the soil to vaporize, and those vapors can then be extracted by VEWs or MPEs. The vapor is directed into an above ground vapor treatment system and, depending on the project, the vapor treatment system typically is based on granular activated carbon (GAC), steam regenerative GAC, or thermal oxidation. GAC is a porous media which absorbs the contaminate in vapor, and thermal oxidation is the process of destroying the contaminants in vapor with high temperatures generally between 1,200 – 1,800° F.

Once the vapor is treated and is clean, it can be discharged back into to the atmosphere.

However, not all contaminants can be removed via vapor extraction. TCH actually provides multiple methods of contaminant removal and destruction.

The heater wells are heated to about a maximum of 1,200 – 1,400° F and heat is uniformly transferred within the volume of soil. Temperature sensors are installed next to selected heater borings to measure the temperature of the heater.

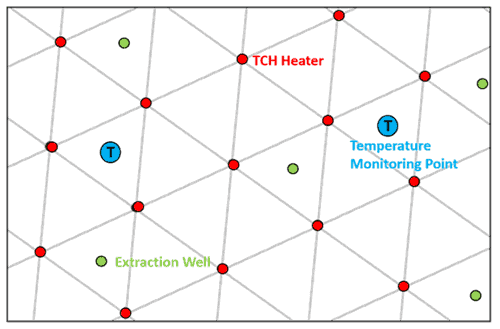

The heater wells are installed in a hexagon grid pattern, usually spaced about 12 to 20 feet from one other depending on application. Along the perimeter of the target treatment zone (TTZ), the spacing is a little tighter to offset the heat losses.

Unlike other thermal technologies, the TCH heater pattern is fairly flexible and can be optimized based on site constraints, such as underground utilities, existing structures, etc.

At the centers of the heater hexagon grid, also referred to as the centroids, extraction points (MPEs or VEWs) are installed along with temperature monitoring points (TMPs). The TMPs measure the temperature at depths every three or five feet in the treatment zone. This allows the thermal contractor to know when the subsurface has reached the desired temperature, and monitor if it’s being maintained as expected.

Heat radiation occurs in the soil nearest to the heater wells, and thermal conduction and convection occur in the soil away from the heaters.

Depending on the soil temperature and site characteristics, different mechanisms can contribute to the removal of the contaminants: evaporation, steam stripping, boiling, removal as non-aqueous phase liquid (NAPL) or dissolved in extracted groundwater, and by chemical reactions (hydrolysis, oxidation, and pyrolysis).

Evaporation: The temperature of the contaminated soil does not need to be at the boiling point of a contaminate to vaporize if water and air are present. This mechanism depends on the increase of vapor pressure of the contaminate in the vapor phase. If the vapor pressure increases, the contaminant of concern (COC) can be evaporated and extracted into the treatment system through the extraction wells.

Steam Stripping: When water is present in the soil, and the soil is heated to the boiling point of water (100 °C or 212 °F), compounds are able to be transported in the steam that is created and into the extraction wells, where they’re treated.

Boiling: COCs can also be removed by reaching the boiling point of the COC itself. Heating the soil to temperatures above 300 °C will vaporize most organic compounds. Once the COC is vaporized, it will travel into the extraction wells and be treated.

Removal as NAPL or in the dissolved phase: For some chemical mixes, heat will substantially decrease the viscosity of a NAPL phase, making the contaminant mass easier to remove by pumping. Also, increasing temperatures will often increase the chemical solubility, and therefore enhance the mass removal by liquid pumping. Substantial mass can potentially be removed by pumping form MPE wells at applicable sites. The pumped NAPL and dissolved mass is separated and treated in the treatment system.

Chemical Reactions: Chemical reactions such as pyrolysis and oxidation occur at very high temperatures (greater than 300° C). COCs will be either destroyed in situ or broken down to smaller molecules and vaporized at these temperatures. For some chemicals, enhanced hydrolysis reactions at temperatures below the water boiling point can also be a substantial mass removal mechanism.

What contaminants can TCH treat?

TCH can reliably remediate many contaminants of concern (COCs). They include…

- Volatile organic compounds (VOCs)

- Benzene, toluene, ethylbenzene and xylene (BTEX)

- Semi volatile organic compounds (SVOCs)

- Polycyclic aromatic hydrocarbons (PAHs)

- Polychlorinated biphenyls (PCBs)

- Per- and polyfluoroalkyl substances (PFAS)

- Coal tars

- Creosote

- Pesticides

- Total petroleum hydrocarbons (TPH)

- Mercury

- And more

TCH can also mobilize large amounts of mass out of the subsurface and remediate sites faster than other remediation methods like pump and treat and “cold” soil vapor extraction.

TCH has removal and destruction efficiencies greater than 99.99% when you include related components, like the above ground treatment system. The typical project duration for heating and treating a site ranges from four to eight months, which is a very fast turnaround for clients to have a safe and quick restoration of the site.

Thermal conduction heating is proven, predictable, and reliable in treating contaminated site. It’s been used all over the world for more than 25 years, and we’ve used it to remediate 80+ contaminated sites. If you would like to learn more about TCH and if it’s the right thermal heating technology for your site, watch our on-demand webinars.

Thermal 101: What Is Thermal Remediation and How Does It Work? >>

05.12.22

Sophia LaRoche

Sophia LaRoche is one of our Data Managers. As a Data Manager, she monitors and processes real-time data that comes in from the field and shares with the project team. She is also involved in system design support, work plan preparation, and engineering fi...