Soil contaminated with semi-volatile organic compounds (SVOCs) is a significant environmental problem that can have serious consequences for both human health and the environment. Fortunately, there’s an effective on-site solution for treating soil contaminated with SVOCs – high temperature thermal remediation.

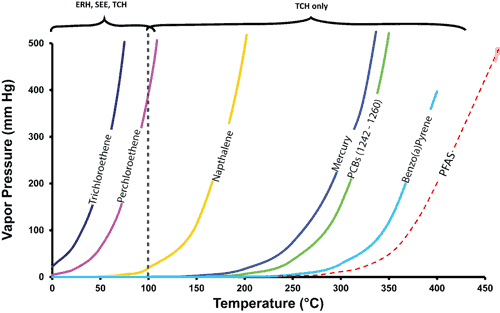

Unfortunately, if your site has pesticides, dioxins, PFAS, PAHs, PCBs, mercury and heavy hydrocarbons, typical thermal remediation treatment at the boiling point of water will not properly mobilize or degrade the contaminants to reach low remediation standard. This is because their chemical properties make them stable even at 100°C. Fortunately, innovations in thermal remediation technologies have made it possible to efficiently heat soil to temperatures much greater than 100°C to successfully treat these problematic contaminants.

What thermal technologies will remove SVOCs?

For VOCs, both Electrical Resistance Heating (ERH) and Steam Enhanced Extraction (SEE) can be excellent thermal technologies, however high temperature thermal conductive heating (TCH) is the only technology that can heat soil to the temperatures required to effectively treat recalcitrant constituents. During high temperature TCH, the soil is heated to 100°C, all the water is boiled off, and then the soil is heated to the required temperature for effective treatment of the targeted SVOCs. For most SVOCs (e.g., PCBs, PAHs, dioxins, pesticides), temperatures between 300 and 350°C result in effective treatment. Higher temperatures between 350 and 450°C have been used for some SVOCs (e.g., PFAS) and sites with very low cleanup levels.

How are SVOCs removed during a high temperature treatment project?

Many of the removal mechanisms for SVOCs are the same as for VOCs, they just happen at a higher temperature, due to the generally higher boiling point and stability of the SVOC chemicals; these include:

Boiling and steam distillation happens on the way to the higher treatment temperatures, when the soil reaches the boiling point of water, and steam is generated. Steam is a more effective evaporator of heavy compounds than air due to steam’s lower molecular weight. The steam helps carry the contaminants out of the soil.

Vaporization mechanisms govern mass removal in many high temperature applications as the soil temperature approaches the boiling point of the targeted SVOC. As the soil is heated above the boiling point of water, the vapor pressure increases making the chemicals more volatile and allowing them to be removed and captured in the vapor phase. During the heating process, the increase in the vapor pressure will increase the mole fraction of the chemical in the vapor phase, resulting in efficient mass removal via the air and steam flowing through the soil. Because of this, it is not always necessary to increase the temperature to the boiling point of the chemical to remove it. Similar to how water evaporates from a glass on a hot summer day.

Chemical reactions play a much bigger role in high temperature applications for SVOC treatment, compared to treatment of VOCs at lower temperatures. The high temperature and long residence time promote in situ destruction of the SVOCs through pyrolysis and oxidation. While in situ reactions are difficult to quantify, more than 80-90% of the removal of dioxins for instance has been documented to be due to in situ chemical reactions. The byproducts of these mechanisms are typically more volatile than the original chemicals, and therefore easier to remove. Overall, increasing the temperature above 100°C addresses the recalcitrance of SVOCs and provides several significant removal and destruction mechanisms for effective treatment.

How are SVOCs treated in the field?

High temperature thermal projects can be completed either in situ or ex-situ. A site-specific evaluation is the best way determine what is most cost effective for your site. Factors include the depth and vertical extent of the SVOC contamination, the depth to the water table, site hydrogeological features, and the presence of sensitive utilities and infrastructures.

The key for successful in situ applications is operating only in the vadose zone. If operating below the water table, full control of the groundwater present is critical to reach the target temperatures. A continuous flow of groundwater, even at small rates, into the targeted temperature zone will buffer the temperature at the boiling point and prevent dry-out and achievement of the higher temperatures required. Dewatering is an option for controlling the water but can be difficult to achieve due to the increased gradient created in the process. If the dewatering system fails during thermal remediation, inflowing water will quench the treatment area and set back the remedy substantially.

The preferred approach for high temperature thermal remediation is to treat the impacted soil ex situ using In-pile thermal desorption (IPTD®). IPTD projects do require excavation of the contaminated soils and placement of the soil in a pile. However, for many sites impacted with PAHs, PCBs, PFAS and dioxins, the extent of contamination is relatively shallow, which makes excavation and treatment in a pile more cost effective than in situ treatment. IPTD also removes concerns associated with controlling and eliminating groundwater influx during treatment and the piles can be designed, sized, and staged to treat a wide range of soil volumes from 100 cy to more than 100,000 cy to meet the required project schedule. High temperature thermal remediation projects typically operate for seven months to one year, and stringent cleanup goals are achieved quickly, efficiently, and reliably.

Successful implementation of high temperature TCH is complex and experience matters. Please contact us if you would like to discuss how thermal remediation might be able to address your client’s recalcitrant SVOC impacts.

04.18.23

Steffen Griepke

Steffen Griepke is the Vice President of Technology at TerraTherm. In this role, he helps clients determine if a thermal remedy would work on their project site and, if so, which thermal technology or combination of technologies would be the most cost-effectiv...