In situ thermal remediation (ISTR)—no matter which of the three main technologies (TCH, ERH, or SEE) is being used—is a process with very limited physical visibility of what is going on within the soil. While temperature monitoring and fluid extraction can be observed, the actual effect on the soil several feet below the ground surface (ft bgs) goes largely unseen.

So how do you know if your goals have been met, if it’s time to turn off the heat and remediation treatment duration?

Even though a lot of the soil isn’t being visibly inspected, there are three specific steps to understanding if thermal remediation has been successful. Let’s dive in!

Numerical Modeling

The first and most obvious option is to look at project progress. During the design of a project, extensive subsurface modeling is performed. This modeling includes site geology input parameters, such as water influx, pore porosity, and soil typing, while also considering the chemical make-up of the contaminants, the co-boiling point of the chemicals, and in situ hydrolysis of the compounds if applicable for the site-specific chemical mixture considered. By looking at these factors, an expected thermal remediation timeline can be constructed.

This timeline can be used as the first step in determining if your project is on track. Using a series of temperature monitoring points (TMPs) to specifically monitor temperature throughout the thermal treatment zone (TTZ) in real time, makes it is easy to see if temperatures have been maintained for as long as was anticipated, and if the mass removed during operations matches up to the anticipated chemical mass, based on the preliminary site characterization. If your projected timeline and results match your actual timeline and results, it’s a good indication your ISTR system is performing as hoped.

While this model is helpful, it is not the final indicator of whether a project is done. A model can be very accurate, but one must never blindly follow modeling, especially on dynamic projects such as thermal remediation projects. Since mass estimates can be high or low, the chemical composition can be different than initially characterized and project interruptions can occur, the project progress provided by the modeling is used to gauge progress early on. It is also used to know when to look at the most reliable indicator, which is the site’s “diminishing returns.”

Diminishing Returns

Diminishing returns is a term found in many industries. It is defined as the marginal decrease in output compared to the rate of the input. In the sense of thermal remediation, diminishing returns relates the reduction in contaminant mass removal from the peak removal rate observed during operation in disproportional terms to the amount of energy delivered to the subsurface.

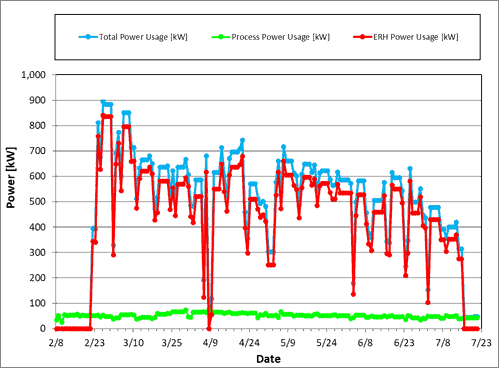

Throughout a thermal project, energy input is required to maintain the subsurface temperatures, whether that energy comes in the form of steam, electrical currents, or conduction. Initially, energy input is higher, but once the temperature goal is met, the energy input often remains nearly constant through the end of the project.

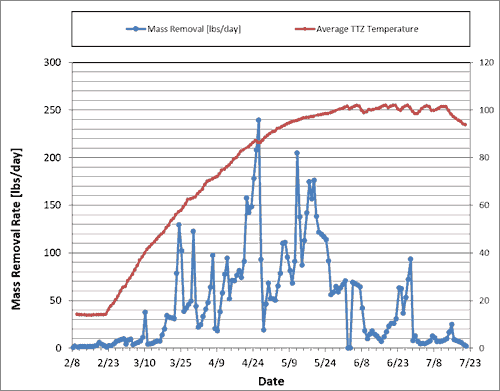

While the energy input stays fairly constant, the mass being removed from the treatment area decreases over time as the amount of chemicals depletes. Mass removal, in the vapor and liquid forms, increases as the site’s temperature gets closer to the expected treatment temperature (often considered to be 100°C). Once it reaches its peak removal, it begins to decrease asymptotically towards zero.

As you can see from the figure above, the temperature eventually steadies out at 100°C and the mass continues to decrease due to the source of the chemicals being depleted during the operational period. Using this data analysis and the modeled time frame, the final step to determining if a site’s goals have been met can be implemented. If both the time frame and the model show the diminishing returns are occurring, it is time to initiate soil sampling.

Soil Sampling

Meeting project goals at a thermal remediation site is often hard to prove initially. While initiating soil sampling early is the most effective method, it is not cost-effective, especially if the site is not at its goal yet. Therefore, to determine whether a site is clean, it is best to first look at the projected status of the operation and then to confirm it with operational data to prove that diminishing returns are in effect and that providing more energy and longer operations will not provide substantially more mass removal. Following the confirmation of these two steps, it is time to initiate soil sampling.

At the end of the day, the best and final way to confirm if a site is at its goal is by completing hot soil sampling. Once diminishing returns are shown from the project data, soil sampling is commenced to confirm the diminishing returns. Through the analytical analysis of multiple samples from different soil boring locations, the soil concentrations within the subsurface can be determined and provide evidence that the site goals have been obtained.

When you’ve put in the effort and expense of designing and implementing a thermal remediation solution, it’s crucial to know that your site goals have been reached by the end of the project. If you’d like to work with our experts to determine how to set project goals and measure progress and success, please contact us to schedule a call.

08.05.21

Sam Nienstedt

Sam Nienstedt is TerraTherm’s Technologist. He keeps the project management team informed of projects’ statuses by monitoring and processing real-time operational data that comes in from the field and preparing operational reports. As part of the Technolog...