Thermal remediation has traditionally been seen as a high resource and large infrastructure technology, and that has led many consultants to dismiss it in favor of more sustainable remedies.

But what if there were a way to lessen the overall environmental impact of a thermal remedy? What if there were an approach that combined an alternative technology with traditional thermal heating methods that was sustainable and could meet your site's needs?

Luckily, there are sustainable options for using thermal remediation. In today’s blog post, I will share how it can be used it to sustainably address high mass contaminant source zones at your sites.

Technology Selection

Thermal technology selection is an important first step to minimizing resource usage. Should the wrong heating technology be selected, it becomes difficult to meet remedial goals, and a remedy may go on far longer than projected and require replacing or adding new components.

So, how can you determine which thermal heating technology is most suited and sustainable for your site? Answering a few questions can help you narrow down your options:

What is the primary contaminant of concern (COC)?

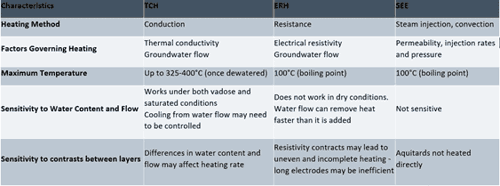

Understanding whether the contaminant is a volatile organic compound (VOC) that may require heating to 100°C or a semi-volatile organic compound (SVOC) which may require heating to upwards of 250 to 350°C will dictate whether only thermal conduction heating (TCH) is acceptable (>100°C) or another technology is suitable, such as electrical resistance heating (ERH) or steam enhanced extraction (SEE).

What is geology?

Having a solid understanding of how variable or complex the lithology is, in addition to knowing approximately what the soil resistivity is and how much it varies across the site, and whether bedrock must be treated, will ultimately determine whether TCH or ERH is a suitable technology.

What is hydrology?

While thermal can be applied both above and below a water table, understanding the rate of groundwater flux rate will help determine which technology or combination of technologies is most effective. Where groundwater flux is high, heating may not be uniform, and in those instances, employing SEE in tandem with TCH or ERH may be the best bet.

Your answers allow you to work with your thermal remediation services contractor to choose a technology that will be effective, predictable, and ultimately have less of an impact on resources.

Target Treatment Zone and Starting Mass

The second step in designing a sustainable thermal remedy is defining the thermal treatment zone and understanding the distribution and approximate amount of mass present at the site.

Extensive site characterization helps you and your thermal contractor understand what, where, and how much mass is present at a site, and how to efficiently recover and treat that contaminant below and above ground. With that information, there’s no need to overdesign, overbuild, or overtreat.

For example, you and your contractor may find that a site should be heated to the ground surface, which would warrant the installation of a vapor cap to both mitigate any fugitive emissions and minimize groundwater infiltration and heat losses to ambient air. Because of the characterization data you’ve already obtained and the mass you know is present, appropriate measures can be taken to minimize heat losses and efficiently heat the target treatment zone in the shortest time practical using the least amount of energy. This ultimately helps reduce the energy resources being used in the thermal remedy.

Remedial Goals

Having well-defined remedial goals is extremely important to the overall success of a project. Whether it’s a target soil concentration, a temperature goal, diminishing returns in mass removal, or a combination of all the above, knowing up front what needs to be achieved means your contractor can design the remedy for an appropriate duration.

When remedial goals, shutdown criteria, and the verification sampling process are not clearly established, decisions about when to turn off the thermal remedy become convoluted. In these cases, the system may be operated longer than needed, and unnecessary water and power are used in the process. Ensuring goals are agreed upon by stakeholders at the beginning of a project is key to running a sustainable remediation project (no matter the technologies used).

Data Management

Once a thermal project is underway, one of the best ways to assess the project’s performance and resource usage is through the data being generated from the remedy. Keeping a close eye on the mass and energy balance, as well as site temperatures, will help determine whether the net heat being added into the subsurface is consistent with modeled expectations.

Should there be a deficiency found in the mass and energy balance or a lag identified in the temperatures recorded in the target treatment zone, adjustments can be made to allow the project timeline to remain intact, which reduces resource usage. Additionally, tracking mass removal rates as a function of the energy being injected into the subsurface allows your project team to determine whether diminishing returns have been reached. This can help stakeholders decide whether verification sampling is warranted and keep a project on schedule. As with the other points, shutting the thermal remedy off in a timely manner conserves resources, increasing the sustainability of the project.

Equipment and Resources

Thermal remediation projects are often able to reuse equipment and resources from one project to the next. That’s why high-quality materials are used in the fabrication of thermal treatment equipment. They can be reused many times before being retired which not only reduces the cost to you, but also reduces the carbon footprint associated with the thermal remedy.

Where possible, your thermal contractor should consider resources and materials—above ground treatment systems, well materials, heaters, etc.—that are already available before purchasing or fabricating something new.

Low Temperature Thermal Treatment

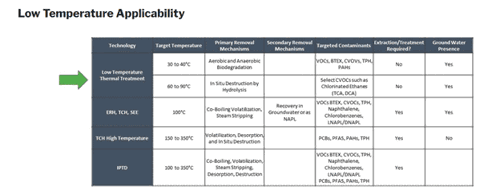

In some instances, a low temperature thermal approach to thermal remediation may be suitable for your site. When a site is already being targeted for aerobic degradation, anaerobic degradation, and/or abiotic degradation of a contaminant, low temperature thermal can be used to help increase the degradation rate and speed up the remedial timeframe.

Because low temperature thermal targets temperatures no greater than 90°C, power usage is significantly reduced. At sub-boiling temperatures, steam production is limited, so you won’t need a below ground extraction system or an above ground treatment system. This also means your drilling efforts and equipment needs are significantly lower.

The lower power demand introduces the possibility of using renewable energy sources, such as solar or wind, to power the wellfield. Standard electrical supplies can also be used when available at a site (e.g., 270/480V, 3-phase).

As with our traditional thermal remedies, the heating components required for a low temperature remedy are robust enough to be used again and again on projects, reducing the material use that contributes to a site’s overall carbon footprint.

While traditional thermal remediation does have a large energy demand and infrastructure footprint, a sustainable thermal remedy is possible with careful planning and selection of the right technology and design approach.

If you would like to learn more about how to choose the best thermal remedy for your project, my colleague Nikole Huard goes through it in more detail here.

If you would like to learn more about low temperature thermal, visit my blog post about it here. And if you’re ready to discuss an upcoming project, we’d be happy to schedule a time to talk.

04.22.22

Hillary Easter

Hillary is one of our Project Managers and is responsible for the effective execution of a complex project within scope, schedule, and budget. She is responsible for establishing the scope and schedule with the client at the outset of a project; managing the p...