In-situ thermal remediation (ISTR) has been widely applied to treat highly contaminated source zones at current and former industrial and military sites. In many cases, these thermal treatment systems are heating and extracting volatile compounds with low flash points, but these extracted compounds are safely contained within extraction piping and treatment systems.

But what happens when a thermal treatment system must be installed at a designated hazardous (classified) area, such as an active chemical plant, refinery, or operating tank farm? This blog post discusses this challenge and how we safely approach these types of thermal remediation projects.

Defining and Classifying Hazardous Areas

Under the National Electrical Code (NEC, NFPA 70) and OSHA regulations, a hazardous (classified) area is defined as a location where fire or explosion hazards may exist under normal or abnormal conditions, due to the presence of flammable, combustible, or ignitable gases, vapors, or liquids; combustible dust; or ignitable fibers. The NEC classifies hazardous locations into several Classes, Divisions and Groups (or Zones and Groups) to define the type of hazard that exists, and under what conditions the hazard is expected to be present.

Class I locations (those with flammable gases, liquids and vapors) are divided into two divisions. Class I, Division 1 sites have ignitable concentrations which can exist under normal operating conditions or where leakage, maintenance, or faulty operation can release ignitable concentrations.

Class I, Division 2 sites are those where volatile flammable liquids or flammable gases are used but would become hazardous only in case of an accident or of some unusual operating condition.

Class I hazards are most often encountered in relation to the target compounds addressed by thermal remediation. We don’t often encounter combustible dust (Class II) or fibers (Class III) on thermal remediation sites.

Challenges in Design and Operations

Developing a safe design and successful operational plan for use in a hazardous location is not as simple as selecting appropriately rated parts from a catalog. Safely heating the subsurface to temperatures of 100°C or higher using electrically powered heaters or gas burners in a hazardous area poses special challenges and requires careful consideration during design and throughout subsurface heating operations.

To conform to NEC and OSHA standards for installations in hazardous locations, we conduct a thorough evaluation of the contaminants present in the subsurface, the source of the potentially hazardous atmosphere (which may be a completely different chemical), and the expected operating conditions during the ISTR program.

For example, Thermal Conduction Heating (TCH) was selected to remediate a historic chlorinated solvent release near a loading rack handling a range of flammable fuels and other chemicals at an active bulk storage and distribution facility. The team needed a solid approach for safely conducting an ISTR project within this facility-designated Class I, Division 2 hazardous location.

For example, Thermal Conduction Heating (TCH) was selected to remediate a historic chlorinated solvent release near a loading rack handling a range of flammable fuels and other chemicals at an active bulk storage and distribution facility. The team needed a solid approach for safely conducting an ISTR project within this facility-designated Class I, Division 2 hazardous location.

The facility had dozens of bulk fuel and flammable chemical tanks, with a truck and rail car loading rack adjacent to the planned ISTR wellfield. Portions of the target treatment zone (TTZ) were close to the loading rack and fell within the Class I, Division 2 hazardous (classified) area designated by the facility.

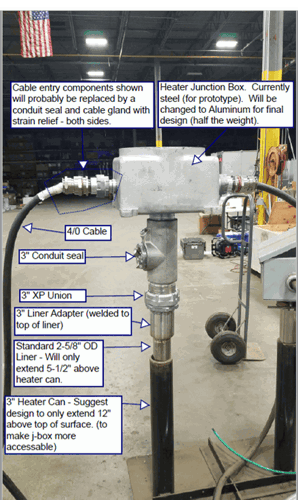

One of the challenges at this site was that the Class I, Division 2 area was not limited to just 18-inches above grade but had no vertical limit. Therefore, any electrical appliances within this footprint, including the electrical boxes and hardware used for connecting the power cables to the ISTR heaters, had to be rated for use in a Class I, Division 2 environment.

To address issues like these, several factors had to be considered when developing the design for a suitable Class I, Division 2 junction box for the ISTR heaters, including:

- Development of a design that incorporated pre-fabrication at the shop with minimal assembly in the field;

- Selection of materials to minimize weight and improve ease of handling;

- Glands that integrated strain relief with vapor-tight seals;

- Ability to service the ISTR heaters in the field if necessary; and

- Maximizing reusability of components despite the need for potted and sealed penetration joints.

This new Class I, Division 2 ISTR wellhead junction box assembly was developed through a collaborative effort between TerraTherm engineering and fabrication staff, and in consultation with our electrical hardware supplier. Over 60 of these new hazardous location-rated wellhead junction boxes were deployed at the facility mentioned above, allowing for the successful completion of the ISTR remediation project adjacent to the fuel loading rack. As a result of attention to reusability in the design, several of these well boxes were subsequently re-deployed to another project at an active chemical manufacturing plant where a portion of the ISTR wellfield extended into a designated Class I, Division 2 hazardous (classified) location.

ISTR a Safe and Successful Remedy for Hazardous Sites

With proper evaluation, appropriate design considerations, and careful operation, ISTR can be safely and successfully accomplished even in locations that are classified as hazardous under the NEC. It’s vital to understand site-specific conditions and requirements, develop sound design criteria, select hardware that is safe, code-compliant, cost-effective, and reusable, and establish an appropriate monitoring program during ISTR heating operations.

TerraTherm has over two decades of experience safely remediating contaminated source zones, even at challenging sites, including active manufacturing plants, in hazardous atmospheres, under occupied buildings, and adjacent to residences. If you are responsible for managing a contaminated site that needs remediation, please contact us to discuss options for safely treating the contaminants.

If you’re considering ISTR technology and would like to speak with an expert, contact our team.

11.28.23

Jim Galligan, PE

Jim Galligan has over 30 years’ experience with in situ and ex situ remediation system design, installation, operation, and troubleshooting, including over 23 years of experience implementing ISTR remedial systems with TerraTherm, having joined the company jus...