Every cubic yard of soil treated is dollars added to a project. Why treat more than you have to?

Modern high resolution site characterization (HRSC) tools provide consultants and remediation practitioners with the ability to develop accurate and complete site characterization for less than 5 to 10% of the total in situ thermal remediation (ISTR) cost, but many thermal remediation projects are implemented with incomplete characterizations or significant data gaps in the conceptual site model (CSM), that may affect thermal remediation performance.

Addressing a known subsurface condition at the start of a project is much easier (and has less impact on overall project implementation and cost) than discovering an unknown condition in the field during implementation. When HRSC is used to build the CSM, you have the opportunity to refine the treatment zone and limit the volume targeted for remediation – which not only makes your project more efficient but also more cost-effective. That’s why, despite the upfront price tag of using HRSC, it makes sense to incorporate it before remedy implementation.

Why HRSC is Relevant for Thermal Projects

As the subsurface is heated, the effects of missing or inaccurate data can become apparent in the form of unanticipated contaminant influx, cooling, an inability to adequately heat certain portions of the defined target treatment zone (TTZ), or extraction of previously unknown chemical constituents. This can result in unanticipated changes or expansion of the original ISTR scope and a corresponding increase in cost or schedule. Given the significant investment in infrastructure and cost to implement an ISTR solution, it is critical to have a complete, accurate, and well-defined understanding of the subsurface contaminant distribution and hydrogeological conditions prior to design and implementation.

HRSC involves the acquisition of data at spatial scales commensurate with the subsurface variables being measured (e.g., soil physical properties, hydraulic conductivity, contaminant concentration and distribution). Typical vertical intervals for data collection are less than 1 foot, and horizontal intervals are measured in tens of feet.

The design of a High-Resolution Site Characterization program is just as important as the tools selected to collect the data. Implementation of a dynamic approach yields the best results, allowing decision-makers to wield the power of real-time data collection to make changes to the field program on the fly.

HRSC investigations can be used to refine and confirm contaminant distribution and hydrogeologic parameters and close known or suspected data gaps. Unlike more traditional characterization techniques, the incremental cost of a single HRSC boring is quite low and this allows characterization professionals to place several borings in a grid in source areas, or in cross-gradient transects along a plume. The closer spacing and distribution of these HRSC locations increases the value generated from the data set. Integrating the acquired HRSC data into a data visualization program after each day of data collection provides for a dynamically refined representation of subsurface conditions to guide ongoing characterization field efforts.

Types of HRSC Tools

Several types of High-Resolution Site Characterization tools are available to collect various types of data at a thermal remediation site. Using technologies like the:

- Membrane Interface Probe – Hydraulic Profiling Tool (MIHPT)

- Waterloo Advanced Profiling System (WaterlooAPS)

- Ultraviolet Optical Screening Tool (UVOST)

- Optical Image Profiler (OIP)

- Cone Penetrometer Testing (CPT)

Our clients are provided a real-time snapshot of subsurface characteristics and contamination. Each of these tools are advanced by direct-push or CPT drilling techniques allowing for data to be collected continuously as the instrument is advanced down the borehole.

Many of the technologies listed above are equipped with multiple sensors returning data on soil classification, hydrology, and contaminant concentration. Individual boreholes provide a snapshot of the vertical distribution of permeable zones and contamination, while strategically located collections of boreholes provide refinement in the lateral directions. Real-time data displays allow for dynamic sampling strategies, so contaminant boundaries can be located with an adaptive step-in and step-out approach.

How HRSC Works in Real Life – A Case Study

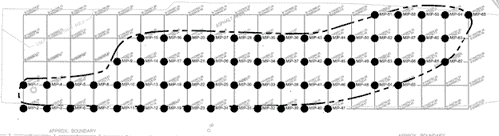

Depending on the scope of the HRSC application, numerous points may be sampled on a refined grid (see figure below). Alternately, contaminant boundaries can be located by progressively drilling deeper and moving outwards until contamination is no longer detected.

The mobility and relatively fast speeds of direct push rigs means hundreds of feet of data can be analyzed daily. The 65 sampling locations shown in the figure were each drilled to 30 feet in less than a week by one drill rig. The resulting HRSC data provided a refined treatment footprint allowing for a targeted remediation, such that no mass was left behind and no dollars were wasted treating unimpacted soil.

Example of an HRSC sampling grid showing 65 points at 20-foot spacing in the horizontal direction.

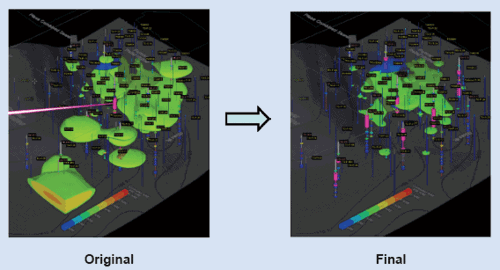

Building a rigorous and accurate CSM is where it all starts. Owners and consultants need a detailed understanding of site conditions and processes to make well-informed site management decisions. Combining HRSC technologies with defensible onsite analytical data and 3D data visualization helps to build accurate CSMs. For thermal remediation sites, the difference between an accurate CSM and an incomplete CSM can translate to hundreds of thousands, and perhaps even millions of dollars of unnecessary expenses.

Contact us if you would like to learn how you can save money by having a proper understanding of your site before implementing thermal remediation.

01.31.25

Amber Bonarrigo

Amber Bonarrigo is a Technical Specialist with a background in thermodynamic and hydraulic modeling. She assists in the subsurface design and numerical modeling during the early design phases of thermal projects. Amber has served as an Assistant Technical Dire...