If you are in need of contaminated soil remediation or have been involved in the procurement of in situ thermal remediation services, you know it’s an involved and often confusing process. It’s challenging to know what to believe when reading about Electrical Resistance Heating (ERH) and Thermal Conduction Heating (TCH) when so much of the information available comes from thermal vendors who may be biased.

This stems from the fact that there are only a few thermal vendors in the industry and they each were founded on one of the technologies (e.g., ERH or TCH). So logically, to compete and win work in the early years of the industry, their primary or technology of origin (i.e., ERH or TCH) was “the best” and the other technologies were not so good. What’s interesting is that today, all thermal vendors offer both ERH and TCH.

However, some of the historic preferences or mythology around advantages and disadvantages remains because in some cases the vendors don’t have as much experience with the other technology and prefer to use their go-to heating method that their company was built on and has lots of capability or equipment to implement.

In this blog post, I’ll bust some of the myths I hear most often and share the unbiased facts with you.

1. TCH doesn’t work below the water table because TCH must dry out the soil for it to be effective.

This is a misleading and untrue myth. TCH is effective both above and below the water table because the thermal conductivity of wet to dry soil typically only varies between 3 and 1 W/(m•K). This means, the conduction of energy and heat away from the heaters is relatively uniform, regardless of whether the soil is wet or dry and that soil above and below the water table can be effectively and predictably heated. In fact, wet soil will conduct heat and heat up faster than dry soil.

Whether you use ERH or TCH below the water table, permeable zones with high groundwater flux can result in excessive cooling and must be addressed in the design process by using closer spacing between the electrodes and heaters, hydraulic control measures, and/or the use of Steam Enhanced Extraction (SEE) for the saturated permeable zones.

2. ERH is not effective above the water table.

Also, a misleading myth. ERH requires soil moisture for the effective conduction of the electrical current between electrodes responsible for heating. Theoretically, in certain geologies (e.g., sand and gravel), the vadose zone soil could be so dry that effective heating using ERH is not possible. However, at most sites, the residual soil moisture content of the vadose zone is sufficient to allow effective heating using ERH.

Water can also be added at the electrodes to maintain electrical continuity with the surrounding soil and provide effective heating of the treatment zone. However, in very permeable vadose zones with limited soil moisture, there is the risk that water cannot be added and distributed sufficiently away from the electrodes to ensure uniform continued heating at optimal power output rates. Basically, the rate of power input boils off the water near the electrode faster than it can be added and distributed, and the electrode ceases to function. Design changes have to be implemented at such sites to ensure adequate heating, including decreasing electrode spacing and increasing the capacity for active water injection and/or adding TCH or SEE to address dry and/or permeable vadose zones.

3. ERH is more energy efficient than TCH.

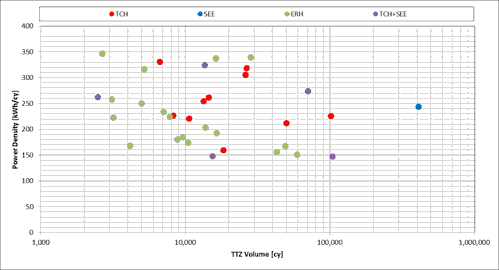

Again, a factually incorrect and misleading myth. We often hear from clients who think TCH consumes a lot more energy because the heaters operate at 500°C to 700°C, the soil around and in between the heaters is dried out and “overheated”, and it causes an excess influx of groundwater into the treatment zone due to boiling at the heaters. We looked at data from some randomly selected ERH, TCH, and SEE sites and that data shows that ERH is not more energy efficient than TCH. The following figure presents this data. The amount of energy required to heat and remediate a site is dependent on the site conditions, COCs (e.g., VOCs or SVOCs), treatment goals, and the rate or amount of groundwater influx, not the specific technology.

4. TCH dries out the soil and results in excessive heating.

Related to the above myth and again incorrect and misleading. With TCH, less than 2% of the treatment zone typically dries out during 100°C treatment in low permeable soil or above the water table, much less so if the site is saturated and the soil permeable. This makes sense as typically, only 10 to 30% of the pore water volume is removed during 100°C treatment, whether ERH or TCH is used. Importantly, any dry regions generated around the heaters (6 inches) are a benefit as they facilitate vapor transport to the vadose zone and recovery.

We also sometimes get asked if TCH dries out the soil causing subsidence? As discussed above, TCH does not dry out a site completely if the target treatment temperature is 100°C. At sites with clays or organic soils, some subsidence (6 inches to 1 foot) can occur in the immediate vicinity of the heaters (~1 ft), but NOT in between the heaters.

5. ERH causes dangerous stray currents

This is like saying your toaster is dangerous if it is plugged into the outlet. Providing a site is carefully evaluated, designed, constructed, tested, and operated, ERH can be implemented safely at most sites. Extensive buried metallic objects need to be identified and removed, if possible, to limit stray currents and short-circuiting of the electrodes, and to ensure safe, uniform, and effective heating.

Routine step-touch-potential testing immediately following any system changes is always good practice and required to ensure an ERH site is being operated safely.

6. TCH requires closer heater spacing and results in a lot more drilling and higher cost.

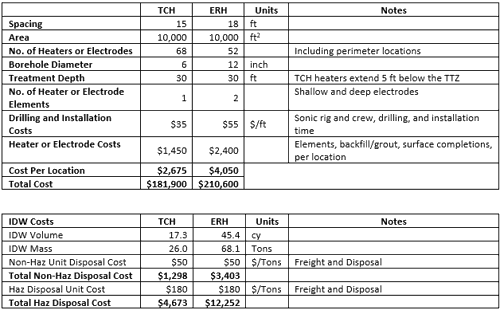

Seems like this should be true, but a full analysis indicates otherwise. TCH typically requires tighter spacing than ERH (e.g., 15 ft vs. 18 ft), but that doesn’t necessarily mean that it’s more expensive because the boreholes are smaller and therefore lower drilling cost. I took a closer look at the numbers for a site we have treated. The following tables provide a summary of the analysis.

To sum it up, the purported advantages and disadvantages of ERH and TCH are more about what is each vendor’s preferred technology and sales hype, rather than actual facts. At the end of the day, both ERH and TCH are two very useful and effective technologies that should be carefully evaluated for applicability, effectiveness, safety, and costs to a specific site’s conditions and limitations. And sometimes it may even make sense to use them together.

Contact me today if you would like us to do a free technology evaluation for contaminated soil remediation for your site.

09.23.21

Alejandro Daza

Alejandro Daza has 18 years of experience in the environmental and water resources industry. At TerraTherm, he supports clients with site evaluations, preliminary conceptual designs and cost for their feasibility screenings. Alejandro is involved in the ...