One of the most important and tangible metrics to a thermal remediation project’s progress is contaminant mass removal. Because thermal remediation is often considered one of the more costly solutions to contaminant cleanup, regulators, property owners, and/or interested parties tend to look at the total mass removed as a measure of success and return on investment.

But it isn’t just regulators or property owners that are concerned about contaminant mass removal. Thermal remediation experts use mass removal estimates to understand how thermal treatment in a remediation project is progressing and what, if any, modifications to system operations are required. By assessing the cumulative mass removed and/or daily mass load, your thermal team can fine-tune the remedy as needed.

But how is contaminant mass removal calculated during treatment and how is this information then used? In this blog post, I will address both the method used to calculate contaminant mass removal and how this information can ultimately affect project outcomes.

Calculating Contaminant Mass Removal

During thermal treatment, there are three potential avenues for contaminant mass to be removed: through the vapor stream, the liquid stream, or as non-aqueous phase liquid (NAPL). Each avenue requires its own considerations and methods for calculating mass removed and are described as follows:

- Vapor – In thermal treatment, vapor mass removal is generally tracked at the inlet to the vapor treatment system (i.e., at the inlet to the granulated activated carbon (GAC) or a thermal oxidizer). Typically, vapor at this point has undergone conditioning to remove any excess moisture and steam condensate that accompanies the vapor stream. Once conditioned, the vapor stream can be effectively screened using many field instruments, most often photoionization detectors (PID) or flame ionization detectors, on a regular basis (often daily, but dependent on project goals). Field instruments provide relative concentration data that can be used to relay daily fluctuations in the mass removal. The relative concentration data can be used to estimate actual mass removal rates and totals if samples are collected concurrently from the same locations for laboratory analysis. Laboratory corrected field concentration data, together with daily vapor flow readings that reflect the flow at the vapor sample point, are the foundation of vapor mass removal calculations.

- Liquid – While generally not as significant an avenue for mass removal for most contaminants targeted for thermal remediation (e.g., CVOCs), the liquid stream is also used in total mass removal estimates. Like the vapor phase, the liquid phase is often tracked at the inlet to the above ground liquid treatment system (i.e., inlet to the liquid GAC vessels). At this point, the liquid stream has also been conditioned by cooling and phase separation to the removal of any NAPL, such that just dissolved contaminant will be accounted for in the liquid sample. The liquid sample is collected and submitted to a laboratory for analysis for the site contaminants of concern (COCs). The mass found in the liquid sample, together with flow rates of the liquid stream through the liquid treatment system, are the basis of mass removal estimates in the liquid phase.

- NAPL – Tracking of NAPL is generally more straightforward than liquid and vapor as it primarily focuses on the amount of NAPL being physically accumulated. The volume of NAPL is quantified by direct measurements of whatever holding vessel is being utilized at a particular project (tank, drum, etc.). In some instances, the NAPL may be characterized by a laboratory for its chemical composition and physical properties such as density, flammability, etc., while in other cases an assumed density is used. At some sites, calculating the contribution of mass from the NAPL can be more complicated due to the nature of thermal remedies and the design of the extraction and treatment systems. This is because NAPL is often removed in batches and separation or settling of the NAPL may occur over time, which may affect volume measurements, which subsequently affect the mass estimate. Similarly, depending on the NAPL density, separation of the NAPL from water in the liquid stream may be difficult. Despite these noted challenges, using the NAPL measurement together with an assumed or determined density is the foundation of the calculation for determining the mass removed by NAPL.

Other methods can also be used to estimate contaminant mass removal at thermal remediation projects. These methods include quantifying the volume of caustic used to neutralize acids generated through the thermal destruction of COCs in a thermal oxidizer as well as quantifying the amount of GAC used in a thermal treatment project. These methods, however, often rely on the identified project contaminants and treatment design, and both contain inherent variability that can lead to significant errors in the mass estimates for the project. Therefore, the methods described above are the most often used, straightforward means of calculating the mass removed during treatment.

Using Contaminant Mass Removal Data

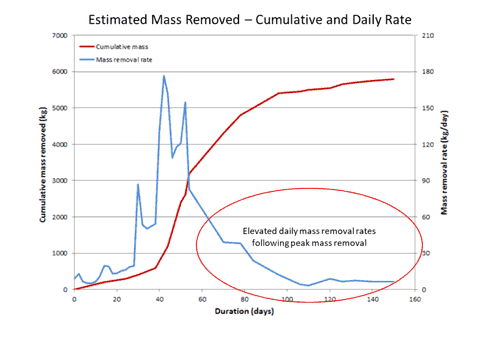

We typically review the daily mass removal rates and cumulative mass removed to understand how thermal treatment is progressing at the site. Daily mass removal rates help the thermal team visualize when peak mass removal has been achieved. Declining daily mass removal rates as treatment duration continues is often used as an indicator that remedial goals have been achieved and that it is time to proceed with confirmatory soil sampling.

Slowly declining asymptotic daily mass removal rates may also be used in an evaluation of whether diminishing returns have been achieved. In some instances, once declining mass removal rates have been observed, we may evaluate the weekly reduction in soil concentrations based on current mass removal rates and soil volume in the treatment area. By quantifying the weekly reduction in contaminant mass, the assessment of whether diminishing returns have been achieved is often clearer and can help guide conversations with stakeholders on whether the shutdown of the thermal treatment is warranted favorable.

Mass estimates, specifically daily mass removal rates, may also be used to determine whether the target treatment zone (TTZ) has been sufficiently heated by the thermal team. A daily mass removal rate that remains higher than expected following peak mass removal may indicate to the thermal team that there was incomplete heating in the TTZ or that mass is entering the TTZ from an outside source. Either scenario will help the team in determining the next steps to the thermal treatment plan.

Calculating mass removal rates for a thermal treatment project is not always straightforward, but it can be one of the most important metrics available to understanding the project’s progress. For further details on the importance of and how to calculate mass removal rates at thermal remediation projects, please see our recent webinar on this topic: https://terratherm.com/webinar/mass-removal-why-its-important-and-how-to-calculate-it/. If you still have questions or want to learn more, reach out to me – I’m happy to help!

12.02.21

Hillary Easter

Hillary is one of our Project Managers and is responsible for the effective execution of a complex project within scope, schedule, and budget. She is responsible for establishing the scope and schedule with the client at the outset of a project; managing the p...