Is it Beneficial to Combine Thermal Technologies?

October 13, 2022

Maybe you have a site with challenging geological features, and you’re trying to figure out which remediation approach can handle all of them. Or perhaps you have a client who is on a tight schedule and needs to treat a source zone and develop the site in a short amount of time?

What many consultants don’t realize about thermal technologies is that while each individual thermal technology is best suited for specific site conditions, you can combine thermal technologies safely on the same project at the same time. In this blog post, I will outline the primary thermal technologies, discuss how they can be used simultaneously, and walk through why your project might benefit from a combined thermal technology approach.

What are the primary thermal technologies?

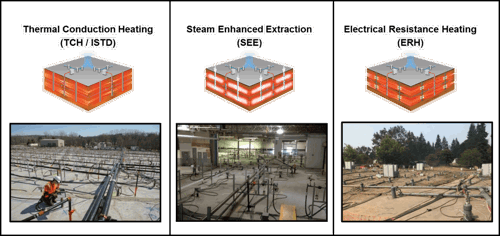

The three primary thermal treatment technologies are thermal conduction heating (TCH), steam enhanced extraction (SEE) and electrical resistance heating (ERH). Each technology employs a different method to heat the subsurface to the required target temperature to treat contaminants via hydrolysis, volatilization, physical mobilization, destruction or stabilization. Equipment selection and utility consumption varies based on the treatment technology. You can find more information about the contaminants, geology and hydrogeology best suited for each thermal technology by watching our Introduction to In Situ Thermal Remediation (ISTR) Part 1 and Part 2 flash webinar series.

How can thermal technologies be combined?

There are many ways to combine thermal technologies on a single project. With the right equipment, multiple thermal technologies can be utilized to treat either in the same area, at different depth intervals, or in different areas of the site. Geological and hydrogeological conditions and contaminant concentrations are big drivers for determining which technologies can be used where, and ultimately when it makes the most sense to utilize a combination of technologies.

For example: If TCH is selected as the primary treatment technology for a low-permeability site, select areas of the treatment zone with higher permeability or groundwater flux can be targeted with SEE to enhance treatment in these areas. ERH can also be combined with other technologies as long as the infrastructure of the other ISTR treatment technologies are electrically isolated from the ERH system, or is installed within an area of the site that has sufficient distance from or a resistive barrier between it and the other conductive wells.

What are the benefits of combining thermal technologies?

Combining thermal technologies can often be the most efficient way to achieve your treatment goals. The benefits of combining thermal technologies include, but are not limited to:

- Minimizing costs associated with multiple mobilizations to treat various areas or depth intervals

- Eliminating extra treatment time required if multiple technologies were installed and executed sequentially

- Utilizing the best suited and most cost-effective technology for each zone which improves treatment efficiency as opposed to utilizing one technology for an entire site

Combined technology case study

Our client had an active manufacturing facility in Florida with chlorinated volatile organic compound (CVOC) contamination below the building. A high-permeability groundwater flow zone was located between two low-permeability zones, and the high groundwater flux and associated cooling prevented the selected ISTR technology, TCH, from properly heating the high-permeability zone. SEE is an ideal ISTR technology for the high-flowing zone but would not have been able to heat the low-permeability zones above and below; therefore, a combined ISTR approach was selected. The design included 413 TCH heater wells and 40 SEE wells to treat the combined high and low-permeability zones. Our team was ultimately able to remove 4,800 lbs of contaminants in the challenging geology below an existing building, that otherwise would not have been able to be removed without taking the building down. The ISTR system operated for eight months.

Combining different thermal and remediation technologies isn’t always necessary, but if you’re facing difficult geological conditions or demanding site goals it’s an approach you should consider.

Let us know if you have an upcoming project you think may be suited for combining thermal technologies, or if you simply want to learn more about how it works.