Cleanup of soil and groundwater contamination present beneath a building is one of the more complex challenges our clients face, made even more so if the building has limited access inside and/or must remain in service and occupied during remediation. The good news is that In Situ Thermal Remediation (ISTR) can be used to address contamination safely and effectively beneath buildings if the correct technology is selected (or combination of technologies), and the system is properly designed, implemented, and monitored. For more than two decades, thermal remediation has been used to treat source zones in and around existing buildings and infrastructure.

When exploring options for treating source zones below a building some of the typical questions clients and consultants have include:

- Can the system be installed inside the building?

- Does thermal remediation below a building require it to be vacated during treatment?

- Are there space limitations for installing an ISTR wellfield inside a building?

- Can the ISTR wellfield be installed at an angle from outside the building?

- Does thermal remediation below a building damage its structural integrity?

Treatment methods and designs are always site-specific, but there are a few rules of thumb that ensure the thermal remedy is safely implemented and that clients’ concerns are adequately addressed without compromising the efficacy of the remedy.

How do you target contamination below a building without installing any thermal infrastructure inside the occupied space?

In some cases, the site owner or consultant indicates that the building over the treatment zone must remain occupied and in operation. This often does not allow access for direct installation of the thermal wellfield inside the building. The preferred approach in such cases is to install angled thermal wells from the exterior perimeter of the building. This approach negates the need to install the thermal wellfield inside the building and is applicable to all wellfield components, including thermal conduction heating (TCH) heaters, electrical resistance heating (ERH) electrodes, steam injection wells, extraction wells, and temperature monitoring points.

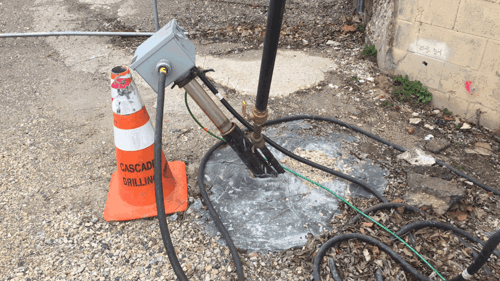

Different variations of drilling can be used for this application to install thermal wells both in an angled fashion (91° to 25° from the horizontal) and in a horizontal fashion (less than 25° from the horizontal). TCH wells and ERH electrodes are often installed in a vertical fan-like pattern to ensure adequate heating and treatment of the entire vertical interval targeted. It should be noted that this approach can be more expensive than installing the wellfield vertically from inside the building as you are using more well materials to reach your desired treatment depths, and it requires a more specialized drilling technique and is often more time-consuming.

How do you safely install and operate a thermal wellfield inside a building?

If access to the source zone is not feasible using angled wells from the exterior of the building and there are no immediate access limitations to the building interior, the wellfield can be installed vertically inside the building, similar to how it would typically be done outside.

Wells can be installed in short sections if there are ceiling height restrictions (8ft minimum), and wellheads can be installed below grade if walking access is required within the wellfield boundary. If certain rooms or areas within the building need to maintain occupied, angled wells can be installed in those areas from adjoining rooms where there is access.

For wellfields installed inside buildings, it is common to limit access by blocking entry with appropriate fencing and signage. Any piping that may achieve an elevated temperature during thermal operations would typically be insulated for personal protection purposes, and any electric cables in the wellfield or surrounding areas would be routed in such a manner to minimize trip hazards and/or placed in conduit.

How do you ensure safe breathing zone conditions inside the building during a thermal remedy?

One of the more significant concerns is protecting the health and safety of anyone that must be inside the building during a thermal remedy, and that includes exposure to chemicals that have the potential to be emitted into the air during treatment. To ensure safe breathing conditions inside the building, it helps to approach it from a few different angles: prevention, engineering controls, and monitoring.

To prevent fugitive emissions and odors during thermal treatment, having the right vapor extraction strategy is critical. Depending on the geological conditions, this may require multiple variations of extraction wells, extraction flow rates, and applied vacuum. Proper air circulation and ventilation inside the building are also substantial contributors to maintaining air quality and comfortable room temperatures. And lastly, a routine air monitoring program can help identify and track breathing zone concerns that may otherwise go undetected.

How can you ensure the structural integrity of a building during a thermal remedy?

Thermal treatment often reduces the moisture content of the soil being treated and can result in the breakdown of organic material in the subsurface. This often sparks concern over potential adverse changes in the geotechnical properties of the soil that support existing infrastructure. We generally recommend having the structural integrity of a building analyzed by a qualified structural engineer or equivalent, as well as a detailed analysis of the geologic conditions below the building prior to thermal treatment. That way educated decisions can be made regarding the design and safety of proceeding. In general, subsidence in the soil as a result of thermal remediation is uncommon and is isolated to certain soil types that are generally easily identified.

What are some limitations that may affect the technology selection or ability to treat below a building?

One thing to examine when considering a thermal remedy below a building is access limitations. Installation of a thermal wellfield requires the use of a drill rig to install the thermal wells. Drill rigs vary in size, technique, and power, which provide options – but those variations also impact if they can fit through doorways, below ceilings, and other building limitations. The access limitations and restrictions of your site will play a role in drilling technology selection. Such drilling limitations may also limit the thermal technology selection for a given site.

Subsurface utilities may also influence the thermal technology you choose and may require changes to wellfield design and subsurface monitoring. Whatever technology is selected, utilities must be clearly defined, including service, size, the material of construction, and active status.

And lastly, soil type and presence of thick layers of high organic content must be properly identified and evaluated to select the best technology for efficient heating and protection of building structural integrity.

To summarize, ISTR can be implemented safely and effectively both from inside and outside a building, depending on access limitations. Concerns over ensuring the health and safety of occupants from exposure to the vapors generated during thermal remediation can be addressed through proper design, implementation, and monitoring. Importantly, ISTR can be used below buildings without damaging the structural integrity of the building. In the end, thermal remediation may be the optimal solution to safely achieve your remedial goals while preserving the use and enhancing the value of your site.

Still have questions? Contact me, I’m happy to help.

11.18.21

Nikole Huard

Nikole Huard is a seasoned Project Engineer at TerraTherm with over a decade of hands-on experience transforming complex thermal remediation challenges into successful outcomes. With a foundation in Chemical Engineering, she has played a pivotal role in design...