Thermal remediation is a robust method that has been used to treat some of the world’s most heavily contaminated sites over the last two decades, but it may not be one you are very familiar with. In this blog post I will explain the basics of thermal remediation, what thermal technologies are available and commonly used, what compounds can be treated, how it is applied to a contaminated site, and what role our stakeholders play in ensuring a successful project outcome.

Want to learn even more? Watch our webinar What is Thermal Remediation? This blog post will give you a head start, but during the webinar my colleague Erin Hauber and I will provide real-life examples and answer all your questions about thermal remediation.

What is thermal remediation?

Thermal remediation consists of the application of energy, in various forms, to heat a contaminated source zone and drive off or degrade subsurface contaminants. Target treatment temperatures of the subsurface vary depending on the type of contaminants being treated and the thermal technology in use, but most commonly a thermal remedy involves heating the subsurface to the boiling point of water (100°C). During heating, the contaminants of concern (COCs) are volatilized in the subsurface and extracted via an above-grade vapor and liquid extraction system that is designed to extract and treat the site COCs. Primary forms of vapor treatment include thermal oxidation and granular activated carbon. Liquids are typically treated using a combination of bulk-phase separation to remove free product from the liquid stream, and granular activated carbon or air stripping processes to remove dissolved COCs.

What thermal technologies are available?

Thermal Conduction Heating (TCH)

TCH consists of applying electricity to heating elements installed in wells within the treatment area, which allows heat to dissipate conductively through the soil. This technology allows for a wide range of temperature control and flexibility within the treatment zone. TCH heaters can operate anywhere from ambient up to approximately 650 to 800°C (1,200 to 1,500°F), giving the flexibility to run at a lower temperature to enhance biodegradation or abiotic processes without the need for extraction and treatment, or heat the treatment zone to temperatures well above boiling to remove hard-to-treat contaminants.

Electrical Resistance Heating (ERH)

ERH consists of applying electricity to electrodes that are installed in a uniform grid-like pattern in the subsurface and allowing the electricity to pass through the soil from one electrode to another below grade. The current flow between electrodes causes the soil to heat, due to the electrical resistance of the soil. ERH allows for similar flexibility and control of temperature as TCH; however, ERH requires water to be present to maintain the electrical conductivity of the soil, so ERH maxes out at the boiling point of water (if the water is boiled off around an electrode, current flow and heating ceases). Even so, this treatment temperature, ~100°C, is applicable for most thermal projects.

Steam Enhanced Extraction (SEE)

SEE involves the direct injection of steam into the subsurface via a network of wells with depth specific screened intervals typically 2 feet long. The steam entering the soil initially condenses at the steam injection well (SIW), transferring the energy and heat to the soil. Over time, a steam zone develops around the SIWs and eventually pushes out reaching the network of multiphase extraction wells installed in between the SIWs. SEE can achieve a maximum temperature of the boiling point of water, +/- 100°C, depending on the elevation of the site and hydrostatic pressure of the treatment zone. This method is best suited for sites with permeable geologies where steam can be readily injected and is often used in combination with TCH and ERH to treat sites with complex geologies consisting of low permeable stratigraphic units and high permeable units with high groundwater flux.

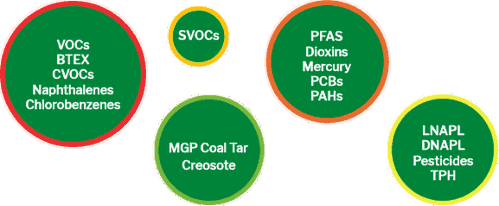

What contaminants can be treated with thermal?

Thermal remediation technologies can be used to treat a wide variety of chemicals. It is commonly used to treat sites contaminated with volatile organic compounds (VOCs), chlorinated volatile organic compounds (CVOCs), and semi-volatile organic compounds (SVOCs). However, also it can also treat sites impacted with high boiling point recalcitrant contaminants like total petroleum hydrocarbons (TPH), manufactured gas plant (MGP) coal tar, dioxins, polychlorinated biphenyls (PCBs), polycyclic aromatic hydrocarbons (PAHs), mercury, etc. These sites are typically treated with TCH, either in situ or in ex situ constructed piles, as TCH is the only thermal technology capable of achieving the temperatures required for the effective removal of these contaminants, typically 250 to 350°C.

Because of the robust nature of thermal, a large range, and at some sites, mixtures of contaminants – with different boiling points, molecular weights, and solubilities – can be targeted by these technologies.

What types of geologies are best suited for thermal?

Thermal can be used to treat virtually all geologies.

ERH and TCH are better suited for low to moderate permeable geologies like clays, tills, silts, and silty sands, while SEE is better suited for the permeable geologies like sands, and gravels. For bedrock systems, ERH and TCH will often be a good choice for the high porosity saturated sedimentary rocks, while TCH is the better technology in fractured metamorphic and igneous rock systems.

Each technology has its sweet spot geology, and sometimes a combination of thermal technologies is required to treat a site. We’ve completed projects with combinations of ERH and SEE, TCH and SEE, and TCH and ERH.

Thermal remediation is a powerful, predictable, and reliable option for achieving low soil and groundwater cleanup goals at many contaminated sites. Hopefully, you now have a better understanding of what it is and if it’s a fit for your upcoming projects. Don’t hesitate to contact me if you have any questions.

To learn more about thermal remediation and watch our webinar, What is Thermal Remediation?

01.10.23

Alyson Fortune

Alyson Fortune joined TerraTherm in 2012 as a Senior Scientist with over 15 years of experience in the environmental industry, including experience with source testing, analytical laboratory testing, and environmental consulting. Alyson is acting as the data q...